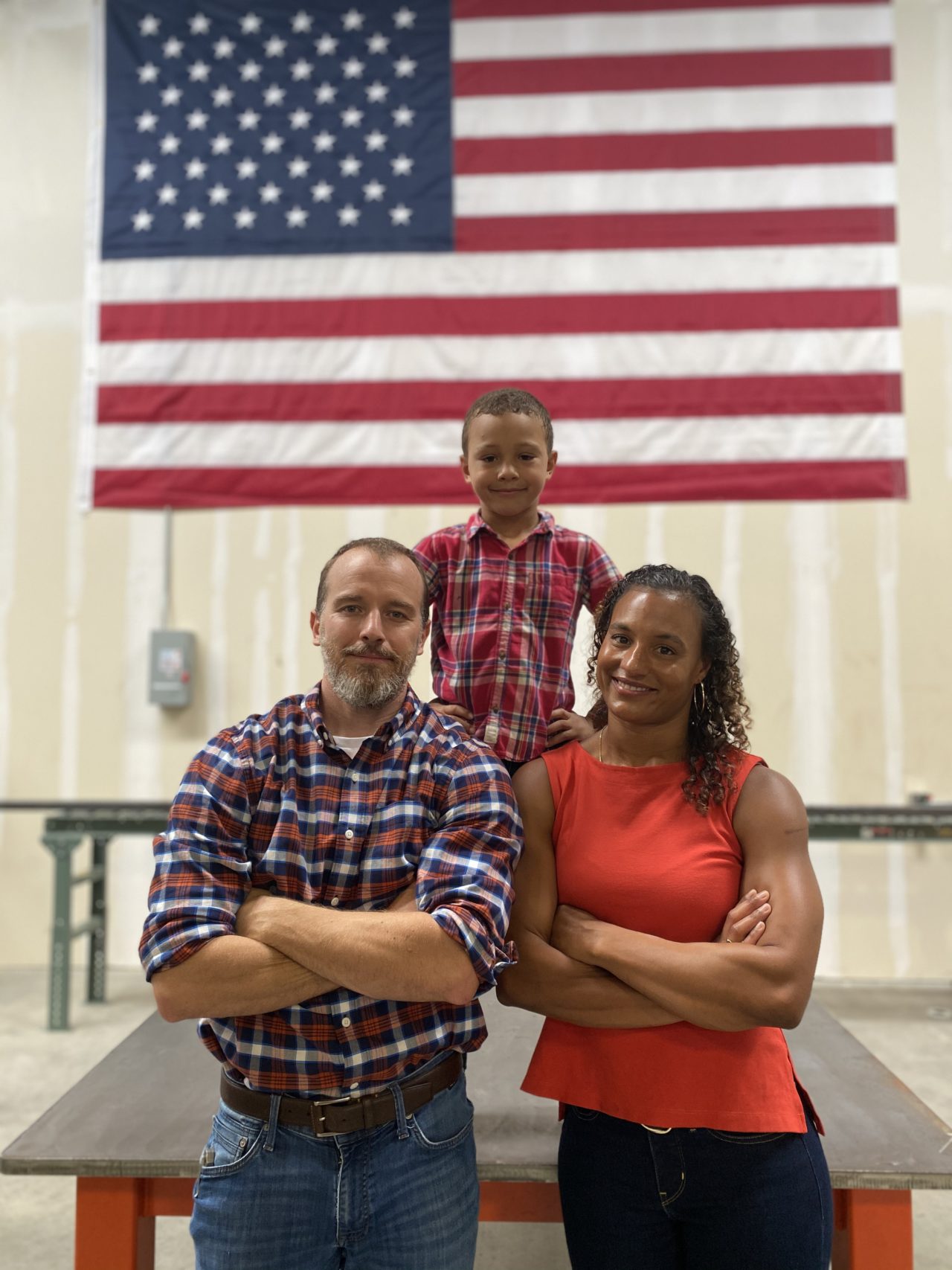

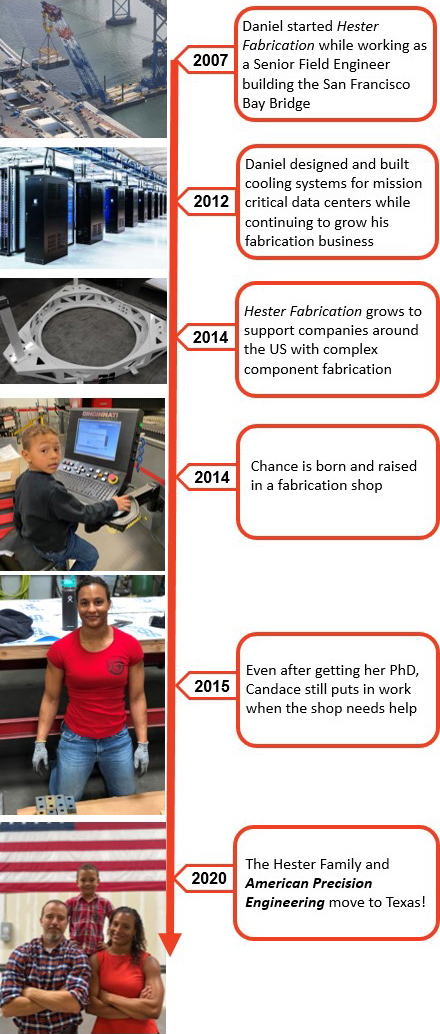

As any family member or business owner can attest, the ability to endure and thrive over time (especially in the presence of a global pandemic) requires flexibility and adaptation. It also requires a keen attention to the evolving needs of those around you. As Daniel’s career evolved from lifting 3-million-pound bridge pieces to designing data center cooling systems, Candace completed graduate school, and Chance was born. Throughout this time, the supports we provided to one another adapted, with an evolving understanding of each persons’ needs. In a consistent fashion, the mission of American Precision Engineering (APE) is to provide engineering and fabrication services based on a durable and adaptable cross-industry understanding. APE uses its Design-Thru-Fabrication methodology to imbed a system of supports to enhance customers’ profitability and viability even in the face of market challenges.

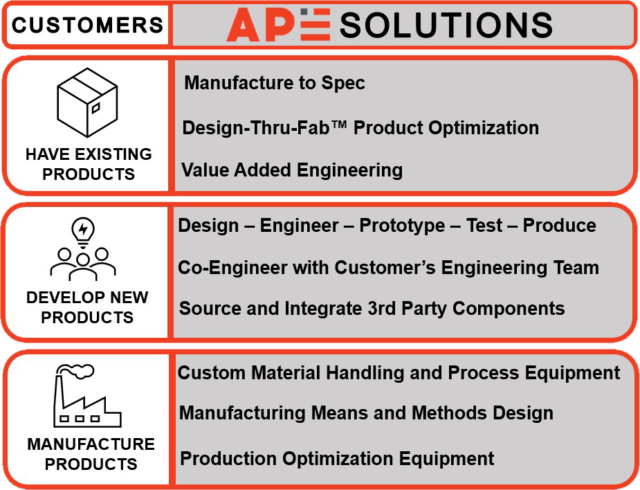

APE’s diverse continuum of customer supports span the product life cycle:

APE understands the opportunities and weaknesses which can undermine the product development process. Without APE, well-intended but ill-conceived designs often integrate inefficient features that introduce unnecessary specialized and expensive tooling. At the least, inefficient features cost unnecessary money. At worst, they introduce weaknesses which put customers at undue risk to market shocks. APE’s methodology considers the entire product lifecycle, taking into consideration granular process components so that APE customers can focus on their strengths. In the face of the most egregious economic downturn in recent times, APE customers have a critical support system in our team which will allow them to thrive into the future. Contact APE to access these services today.

American Precision Engineering:

A family run metal design and fabrication firm built to strengthen the long-term success of industrial and commercial companies

2020 September

COVID and business share at least one trait—they can bring a family together or tear them apart. Our family has remained lucky in both regards thus far. We are healthy and whole, after more than 10 years of marriage and business, even in the face of COVID.

13610 Immanuel Rd, Pflugerville, TX 78660

ADDRESS