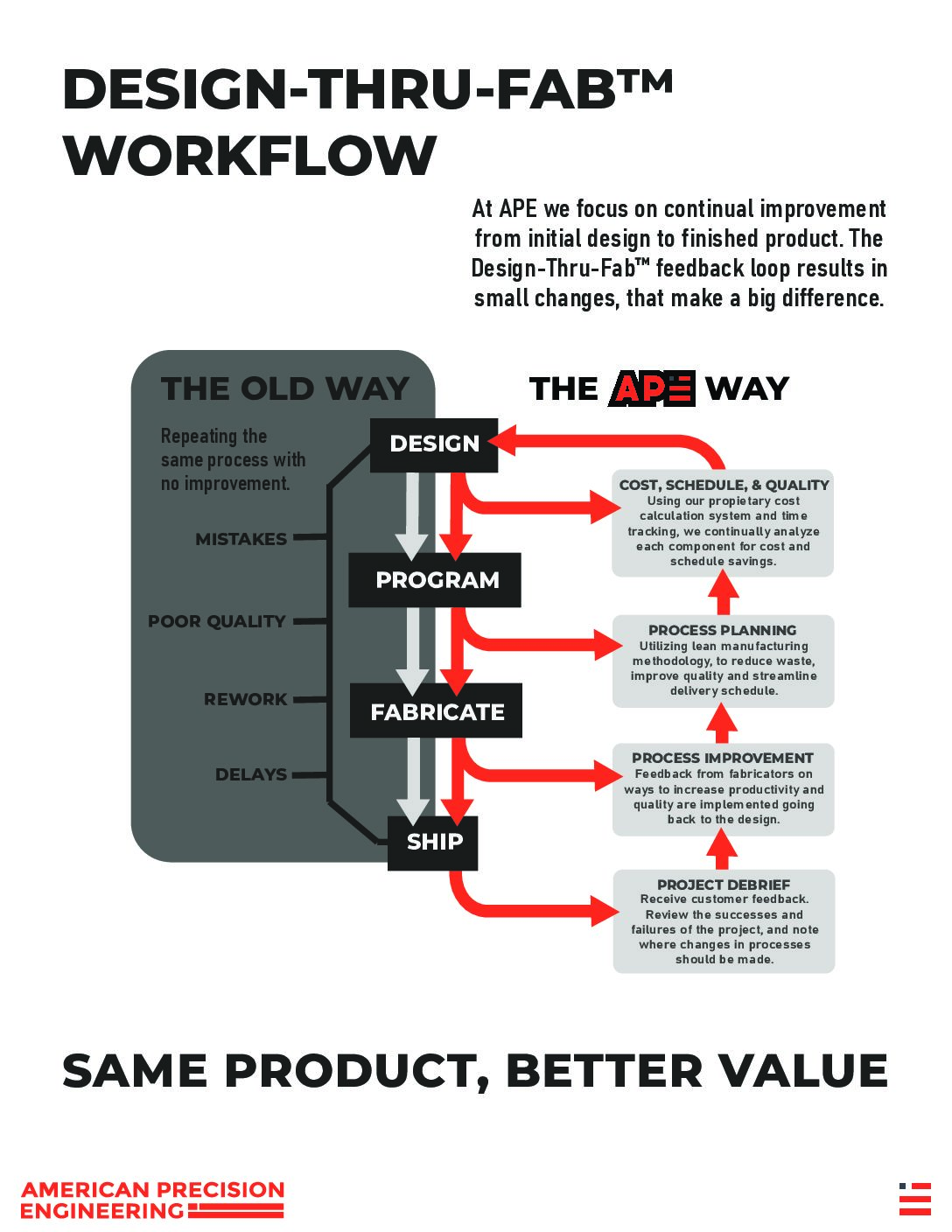

In the early months of the Coronavirus outbreak, we learned of the perils of unanticipated supply chain weakness in the medical field. As governments worldwide worked to stockpile masks, ventilators, gloves, sanitizer, and medication, reliance on a few Chinese manufacturers proved critically problematic. And though in time companies with alternative specialties were able to pivot to provide these goods, many of those efforts yielded too few resources and too late. In a similar vein, many product developers and manufacturers can find themselves with unanticipated weaknesses in their product lifecycle process. They may invest the time of an in-house engineer to detail a model that includes unanticipated weaknesses in the design and/or into their part selection. Or they may rely on a manufacturing process which builds in unnecessary inefficiencies. In either case, developers and manufacturers may integrate unforeseen inefficiencies which cost time and resources, and also leave them open to unnecessary supply chain weaknesses. At APE, we anticipate and alleviate weakness in the product lifecycle for our customers. We provide a range of services to, One mechanism that APE has to improve our customers’ product lifecycle efficiencies is through our Design-Through-Fab (DTF) process.

DTF is work methodology that continuously monitors the project to optimize quality, schedule, and price. Using the DTF method we can utilize APE-specific best practices into the design to enhance production efficiencies. Additionally, APE’s DTF methodology optimizes the interface across project stakeholders, reducing engineering and management resources required by the customer. In this way, DTF creates a continuous improvement loop to make sure changes that improve the project outcome are consistently implemented through each step of the product lifecycle, starting from the design concept and following the project all the way to completion. This assures that the improvements are stable and agnostic to any single part supplier or manufacturer. Therefore, by taking advantage of DTF, our customers avoid inefficiencies associated with the time and resources required to create details that ultimately will not work in the shop context. And using DTF, APE can detail parts to manufacture efficiently, make drawings to flow seamlessly through our shop, and provide the customer with perfectly functioning CAD models and a great product for a good price. Consider a recent project for a large global corporation, that I’ll refer to as Company X. Company X emailed us a SolidWorks model of a stainless steel test chamber used in a manufacturing environment and wants a quote to finish the model and create the required shop drawings. We quoted the job using his model and our proprietary quoting system that is based on historic data and submitted the quote. Because of the design, I anticipated that the customer was going to feel that the price was too high. To head this off, I called the customer to explain why the price is so high. We quote essentially “by piece, and by pound” so that the more pieces the design has, and the more it weighs, the more it costs. So, when a project could be built using 6-8 individual parts, has 48 parts, I know it’s going to be too expensive for what it is trying to accomplish. Despite being disappointed, the seems to understand my reasons for the high price. I assure him that I could submit a price to design the product, and using DTF, I would be able to substantially reduce the production price. But Company X did not see the value of this, as they were convinced that they could improve the design on their own. A few days go by and I get another email from their engineer asking my thoughts on his revised design. I gave him a few pointers, and waited a few more days for the next revision from him. Three weeks and 67 emails later (seriously, 67) he had a design he was ready to fabricate as a first article. The price was still higher than he wanted (and higher than our DTF process would have rendered) but he seemed convinced the prototype would give him the feedback he needed to get the design tweaks down to make it an affordable production run. We are finally off the fabrication phase. But first we are stuck waiting for three weeks for hardware he designed into the door which is only available in Europe. After the hardware arrives, we it will not work with the door design. This requires us to modify multiple parts, make some new parts, and design a custom latch plate. Eventually we finish the project. The engineer is happy with his design and happy with our fabrication, albeit several weeks late due to the delivery of his hardware and the debacle that it caused. About a week after delivery of the first article, company X calls back. During testing, a design failure of the product buckled the door causing a violent explosion. Thankfully, no one was hurt, and no other machines were damaged other than the product itself. At this point, company X became convinced to scrap their design and pay for our services. What was the cost of this lesson to Company X? What unnecessary risks did they take on? What indirect costs were incurred by having their engineer working on this instead of what his normal engineering duties? Just because you can eventually get to a “good enough” result does not mean that it makes business sense for you to do it yourself. Often your overall cost is much less, and your product is much better when you hand it over to APE. Having an engineering department doesn’t make you an expert any more than owning a knife makes you a butcher.

What is Design-Through-Fab (DTF)?

A Case Study on the DTF Value

2020 October 07

13610 Immanuel Rd, Pflugerville, TX 78660

ADDRESS