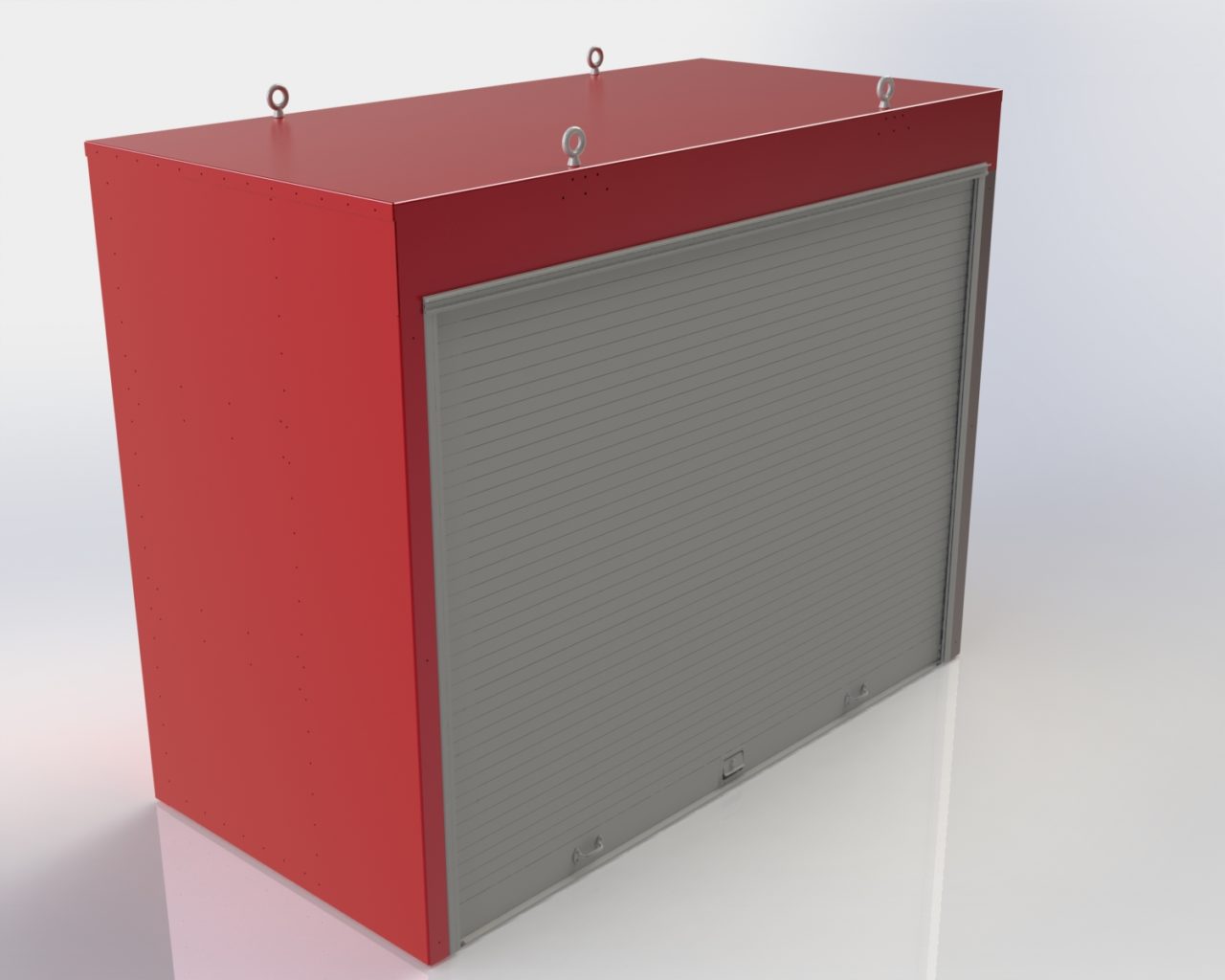

The Challenge:

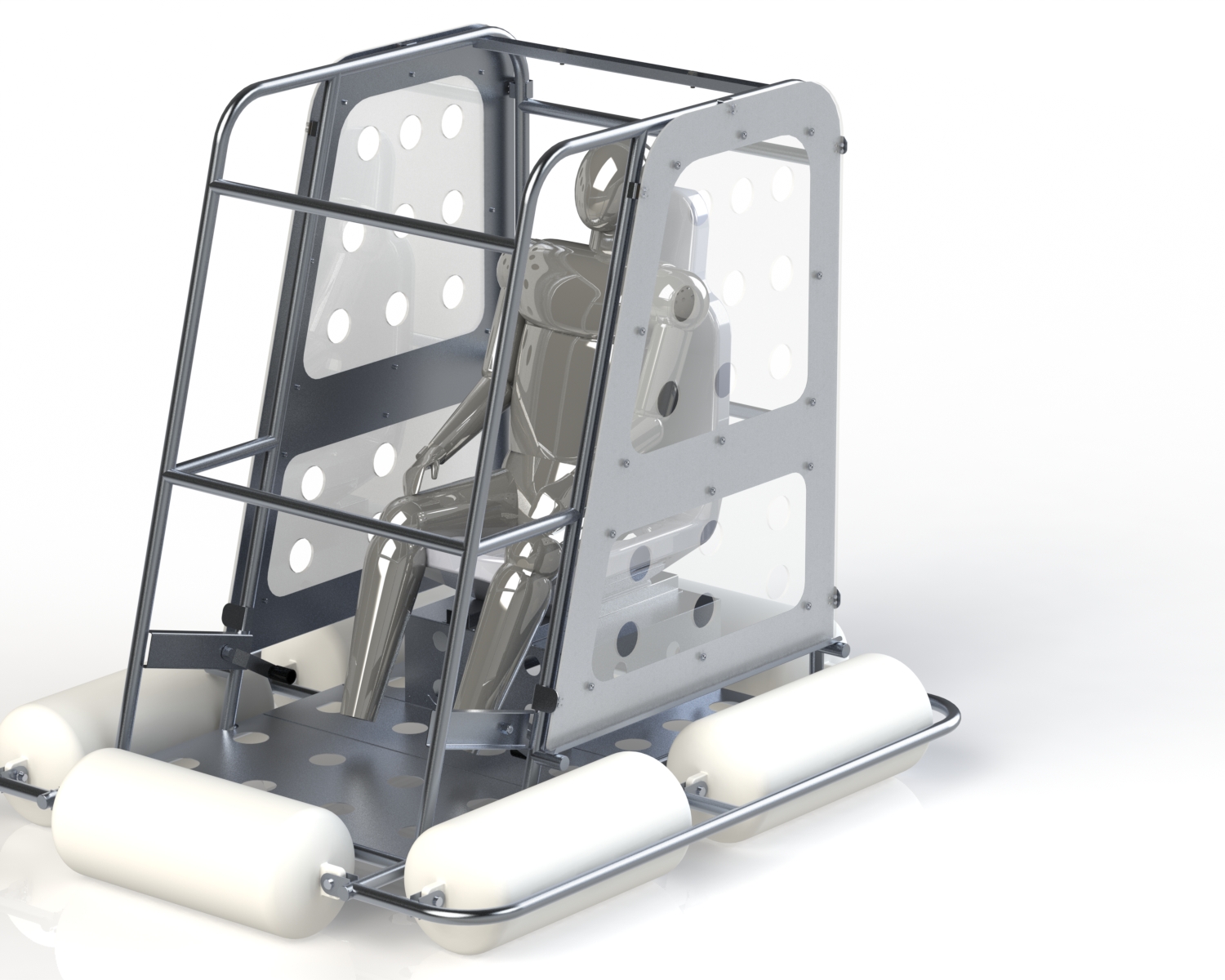

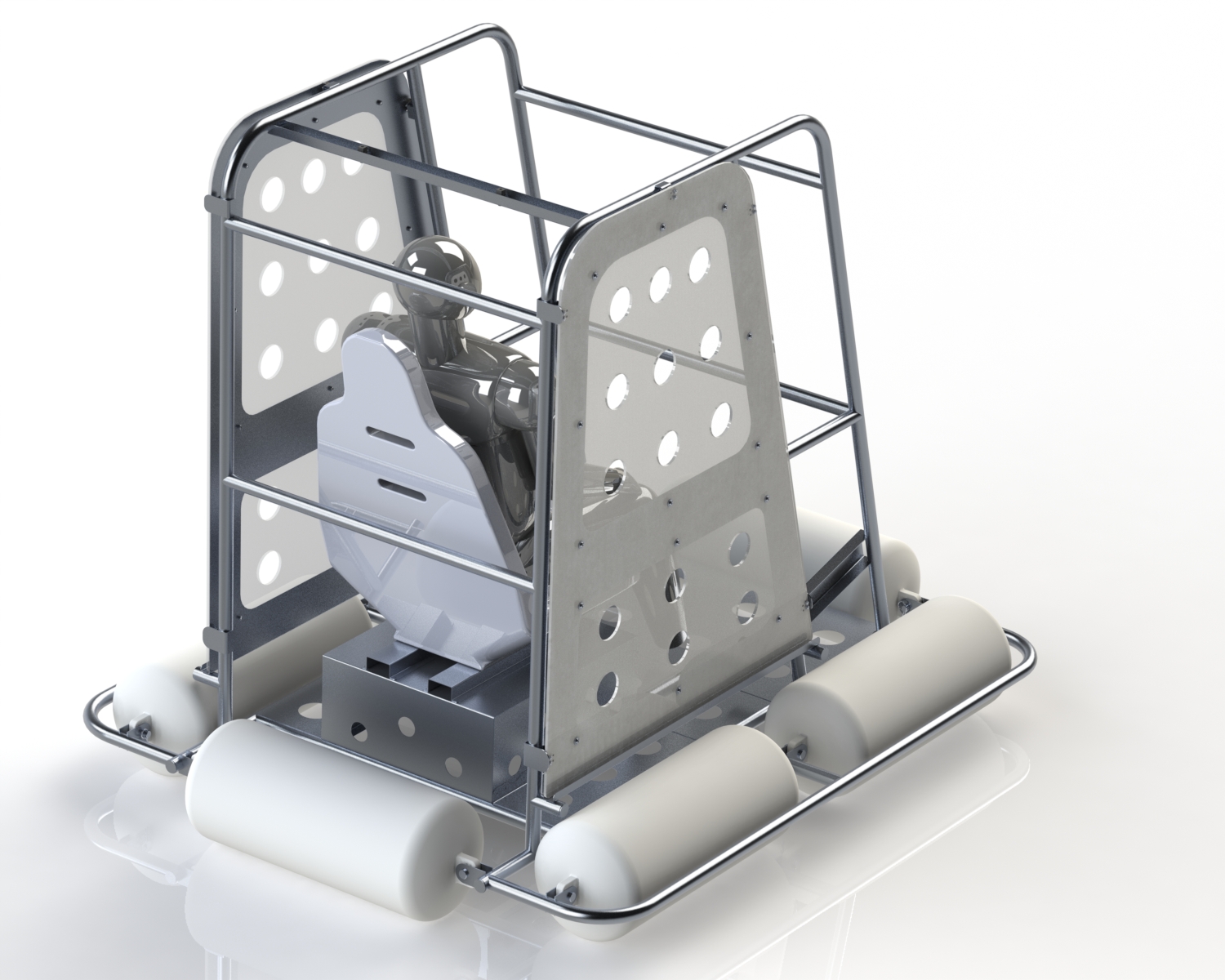

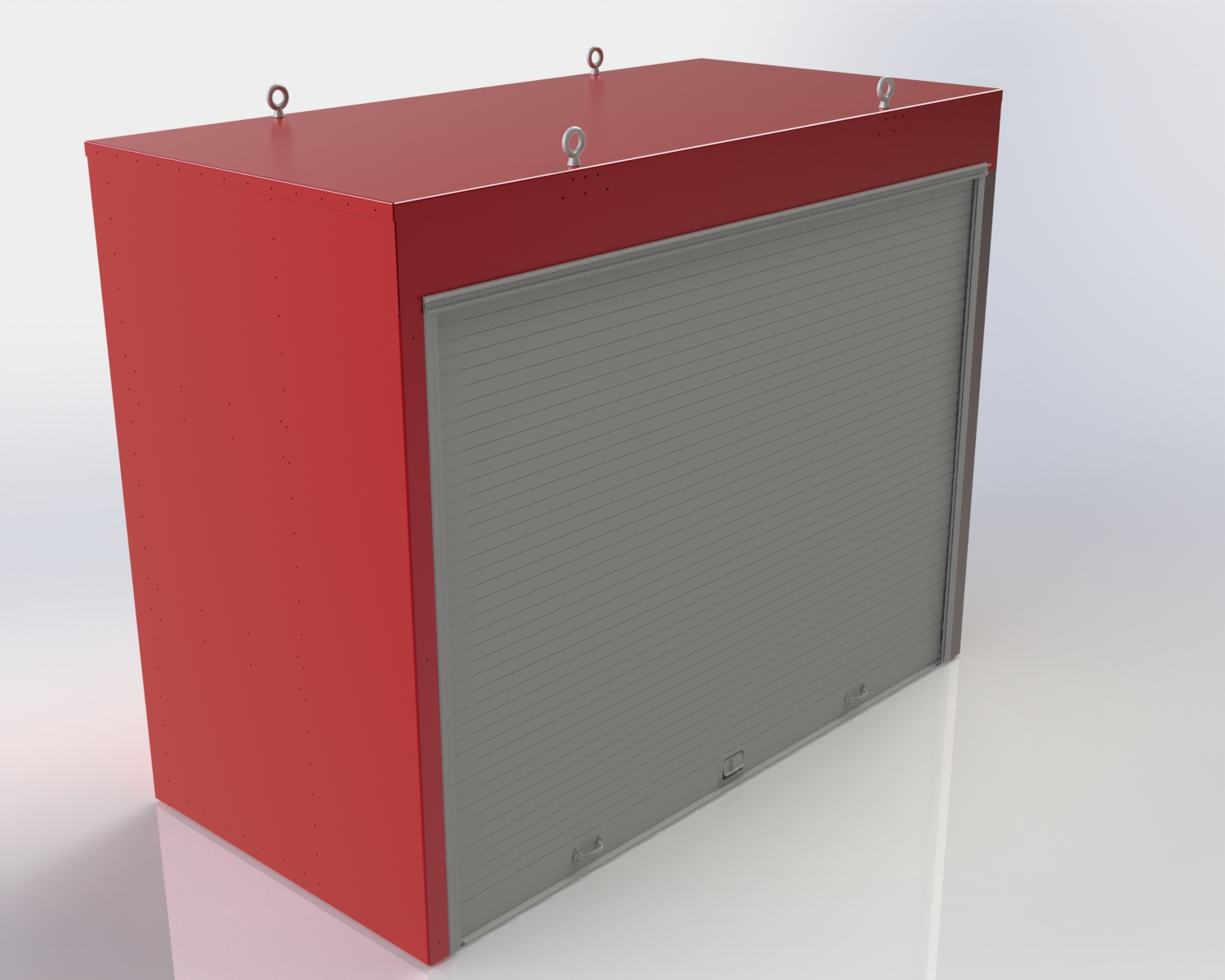

When an aerospace company needed a tool storage solution for their rocket engine test area we were tasked with coming up with a way to secure large wheeled tool carts and protect them from the environment in a harsh desert climate.

Solution:

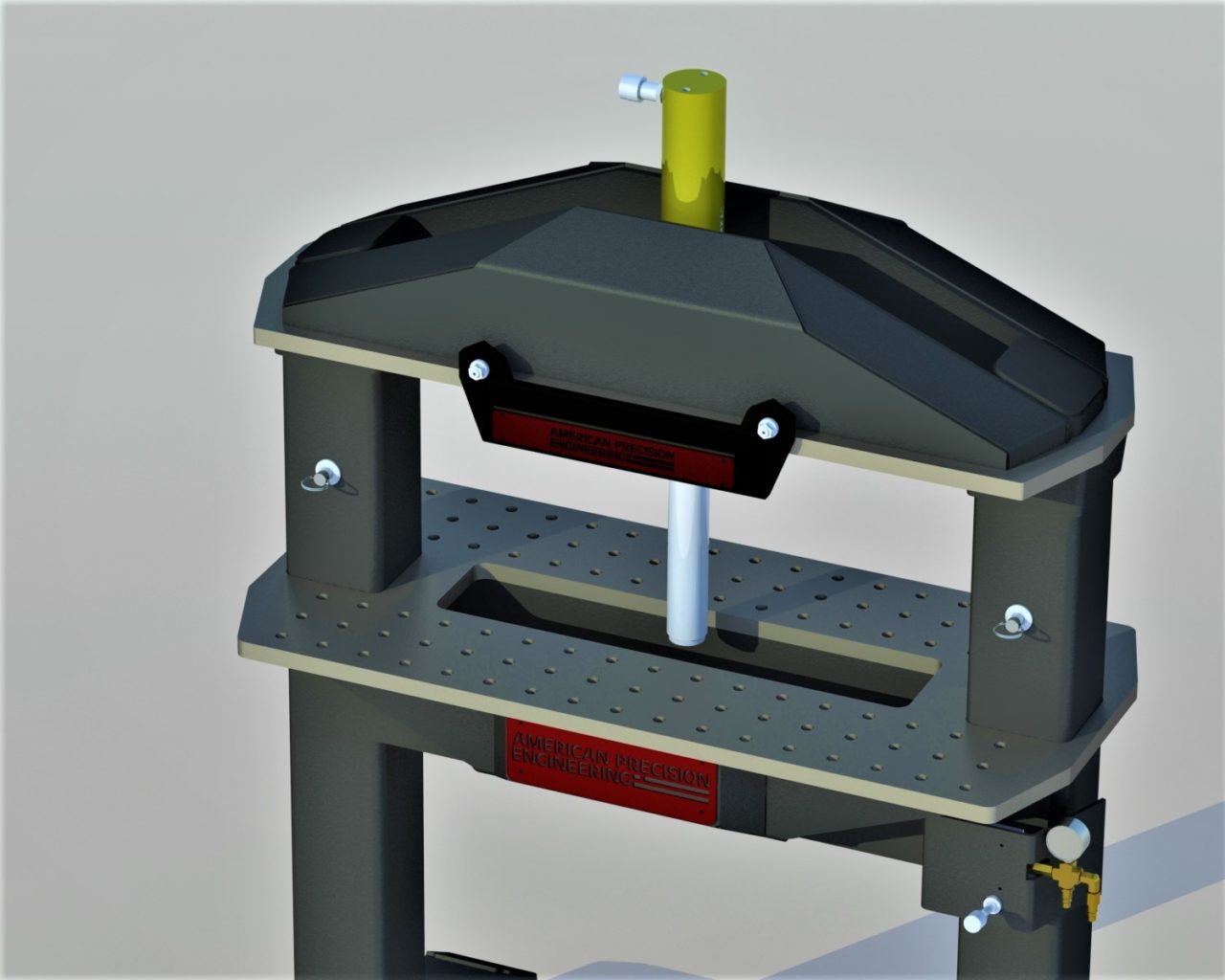

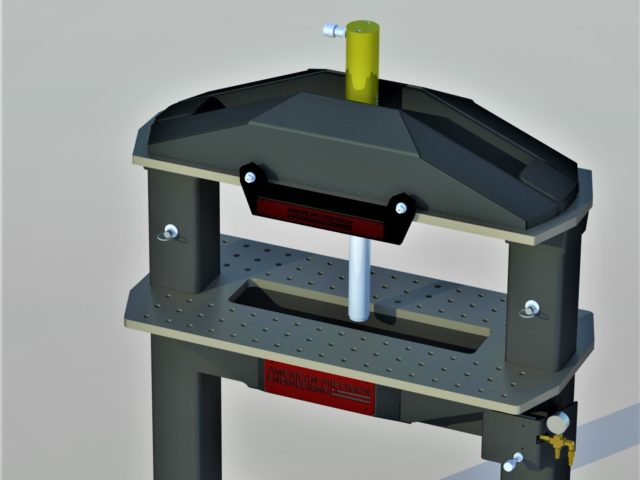

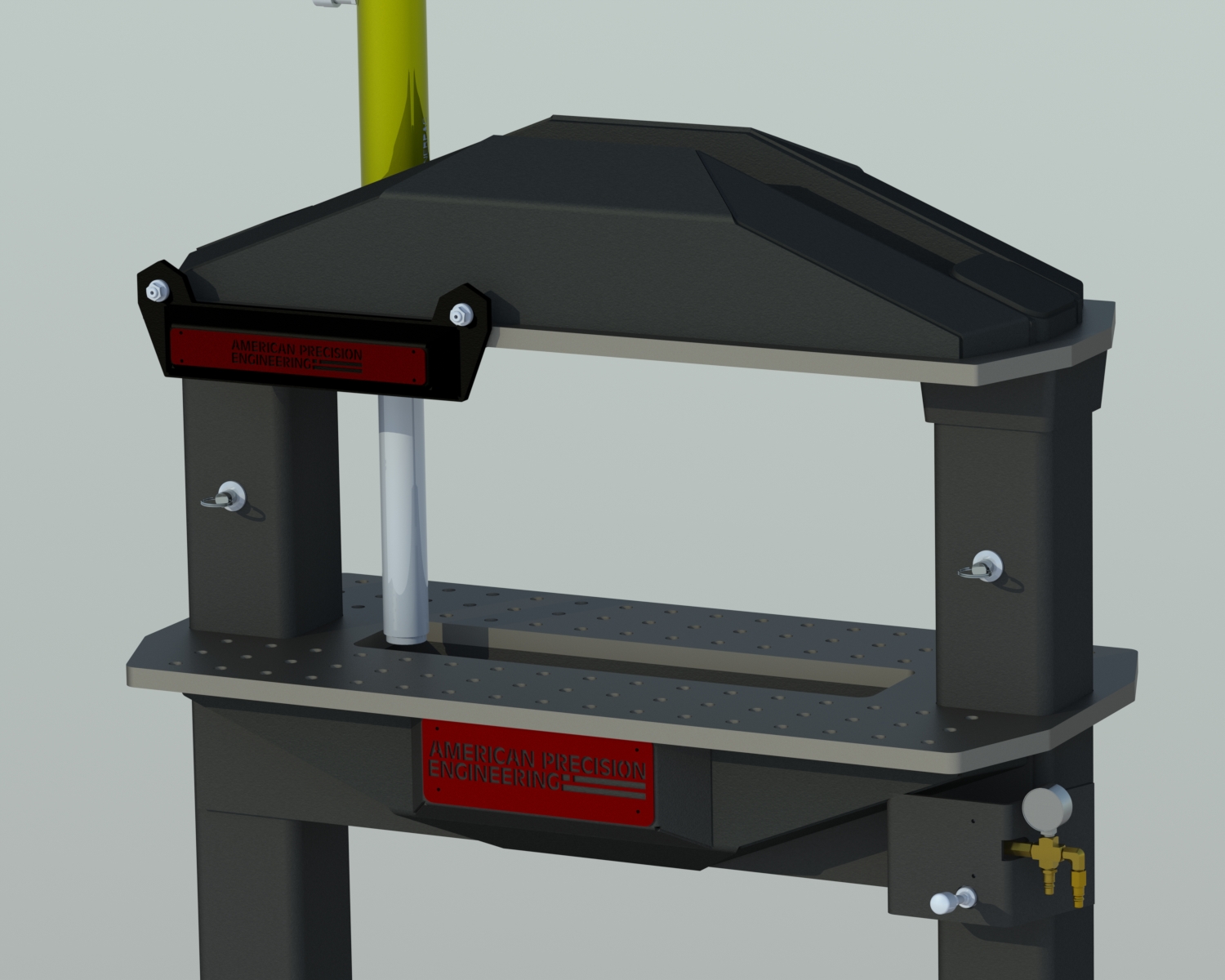

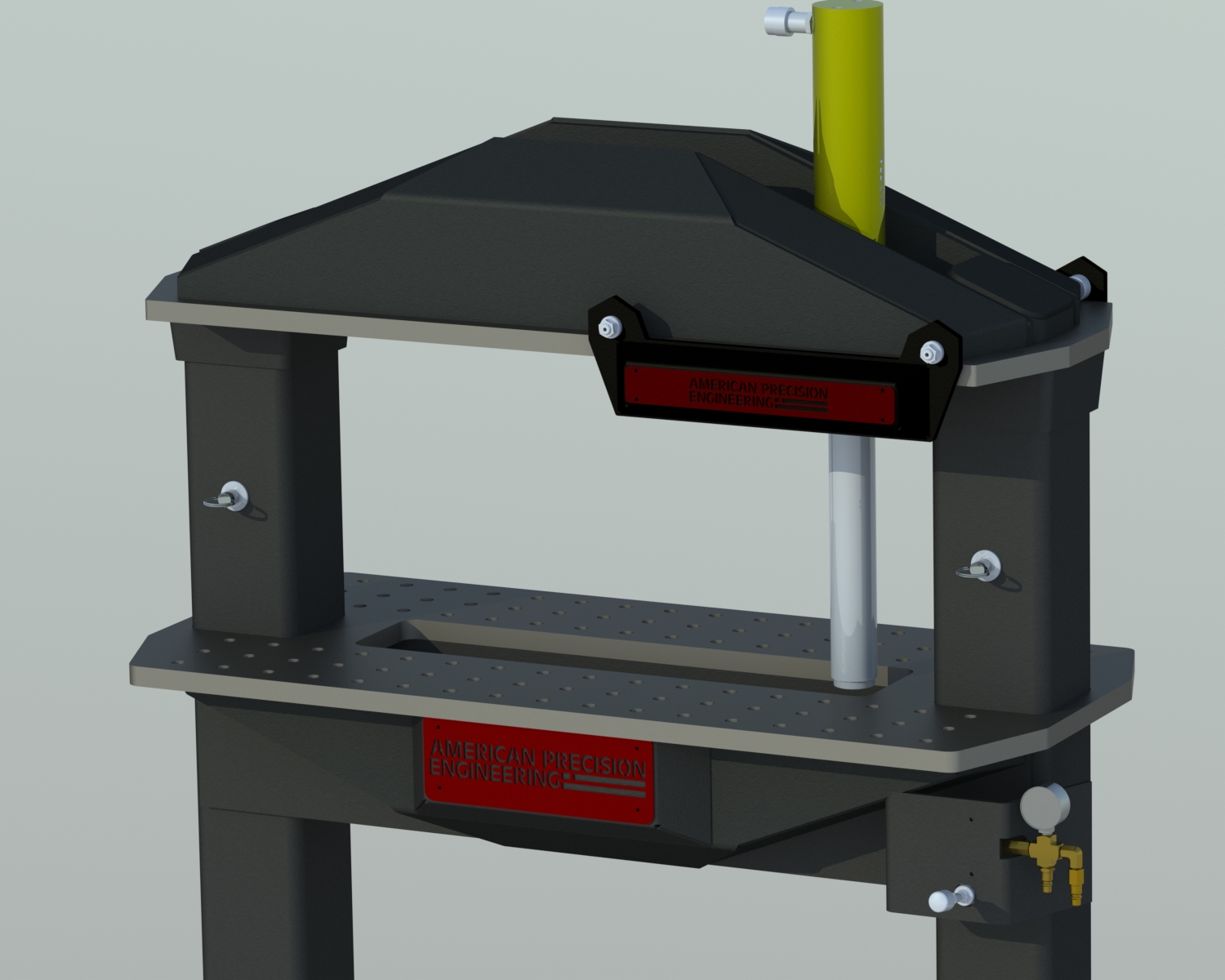

In order to withstand the abuse of life on a rocket test stand in the middle of the desert, we knew that we needed to design using components that could withstand heat, cold, impact, lots of UV sunlight, and of course the normal wear and tear of an industrial facility. It was for these reasons that we selected to use 10 gauge (.135”) mild steel for the body, and supports, and coat the box in a 2-coat epoxy paint designed for harsh environments.

To be able to have security, as well as quick access and durability we chose to use Diamond Rollup Doors. The Diamond doors are built for harsh environments and seal out the wind and the rain.

Since the work on a rocket test stand can run at night we incorporated LED fluorescent lights to give users a bright view. Electrical outlets were also added to allow for charging stations for phones, computers, and batteries.

Our solution ended up being the perfect solution to roll large toolboxes into a safe and secure storage when they were not being used.

The Results:

This custom toolbox was an elegant solution to a storage problem that not only looked amazing, but built to last, and improved the operation in several ways including:

- Decrease in wasted time traveling to get tools

- Convenient area to charge and store batteries

- Better protection of their tools resulting in less maintenance.

- Reduced safety exposure