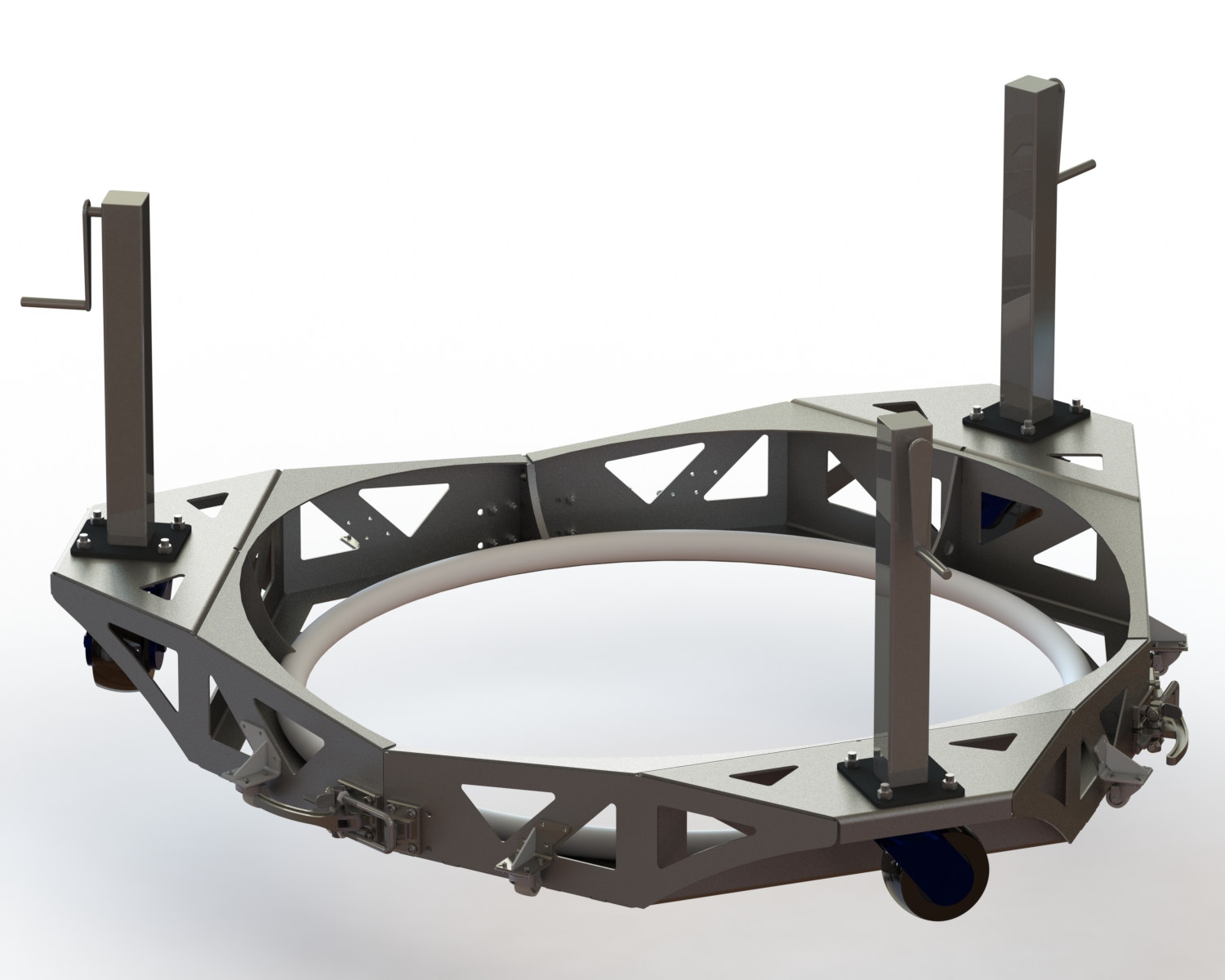

Custom Part Mover

The Challenge:

We needed to make a custom industrial material handling system in record time. A large international corporation had a bunch of oddly shaped, highly delicate, and heavy devices they needed moved into a building in Europe in 2 weeks. This required that we design a custom industrial material handling solution for them with no room for error in record time.

The Solution:

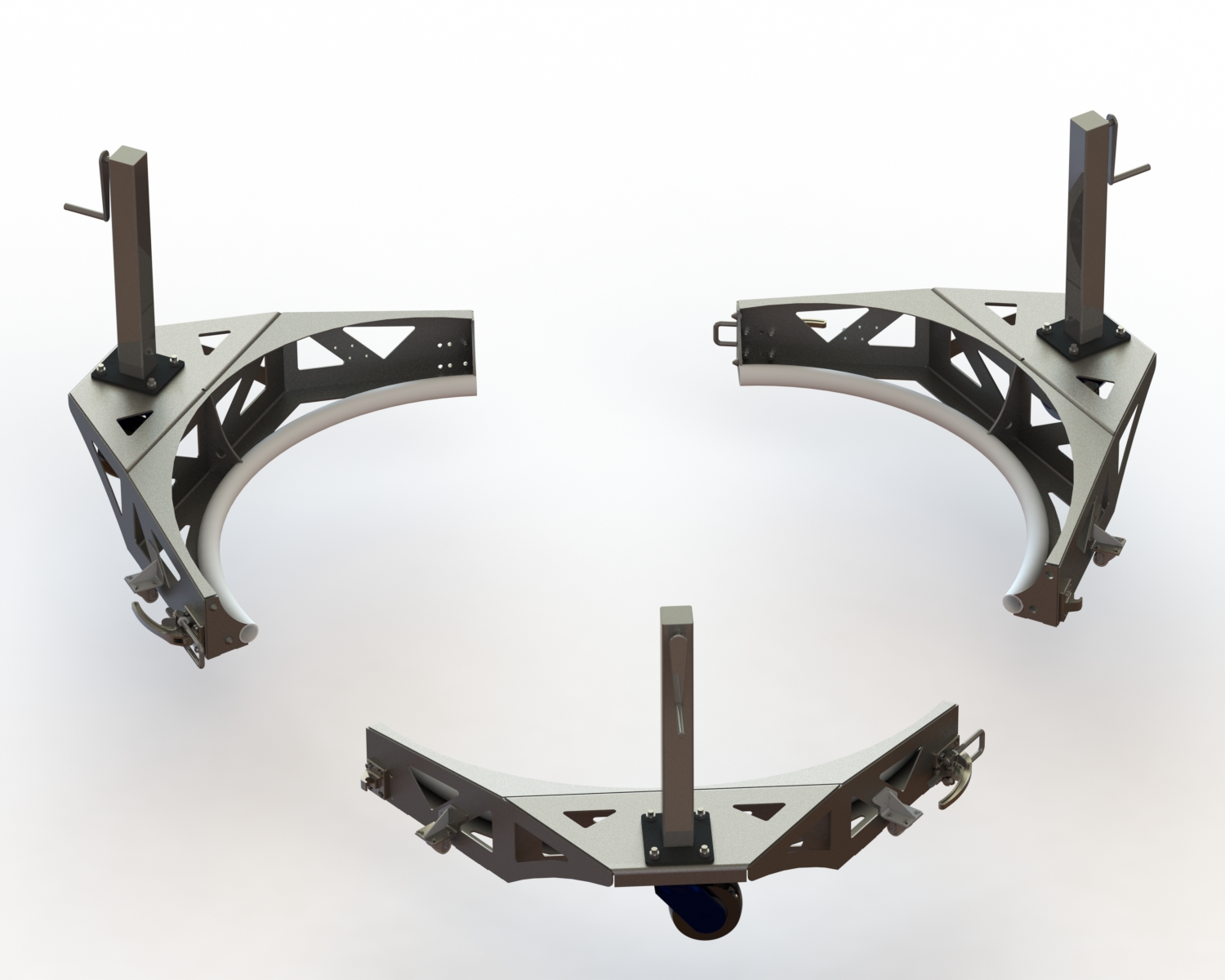

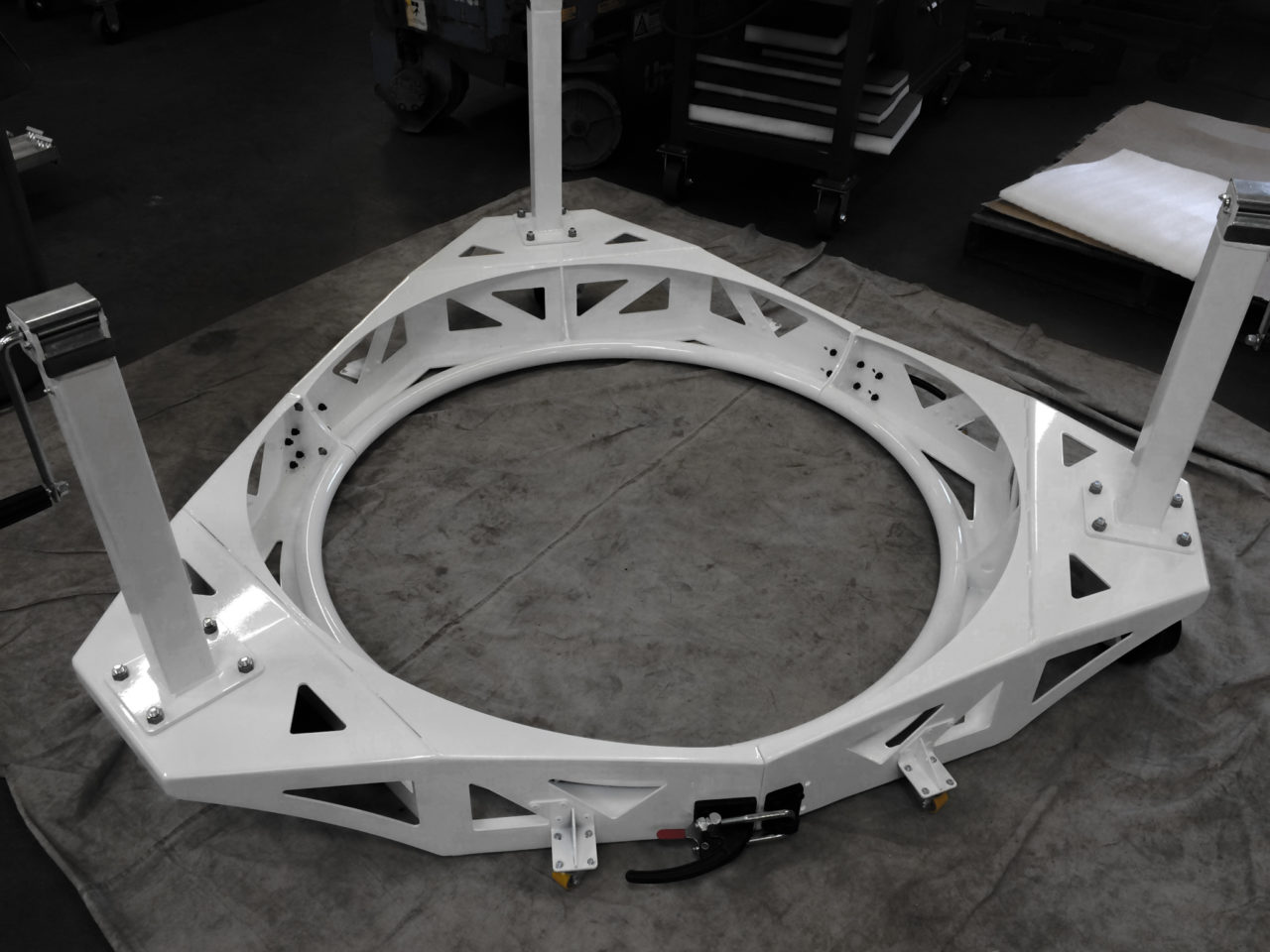

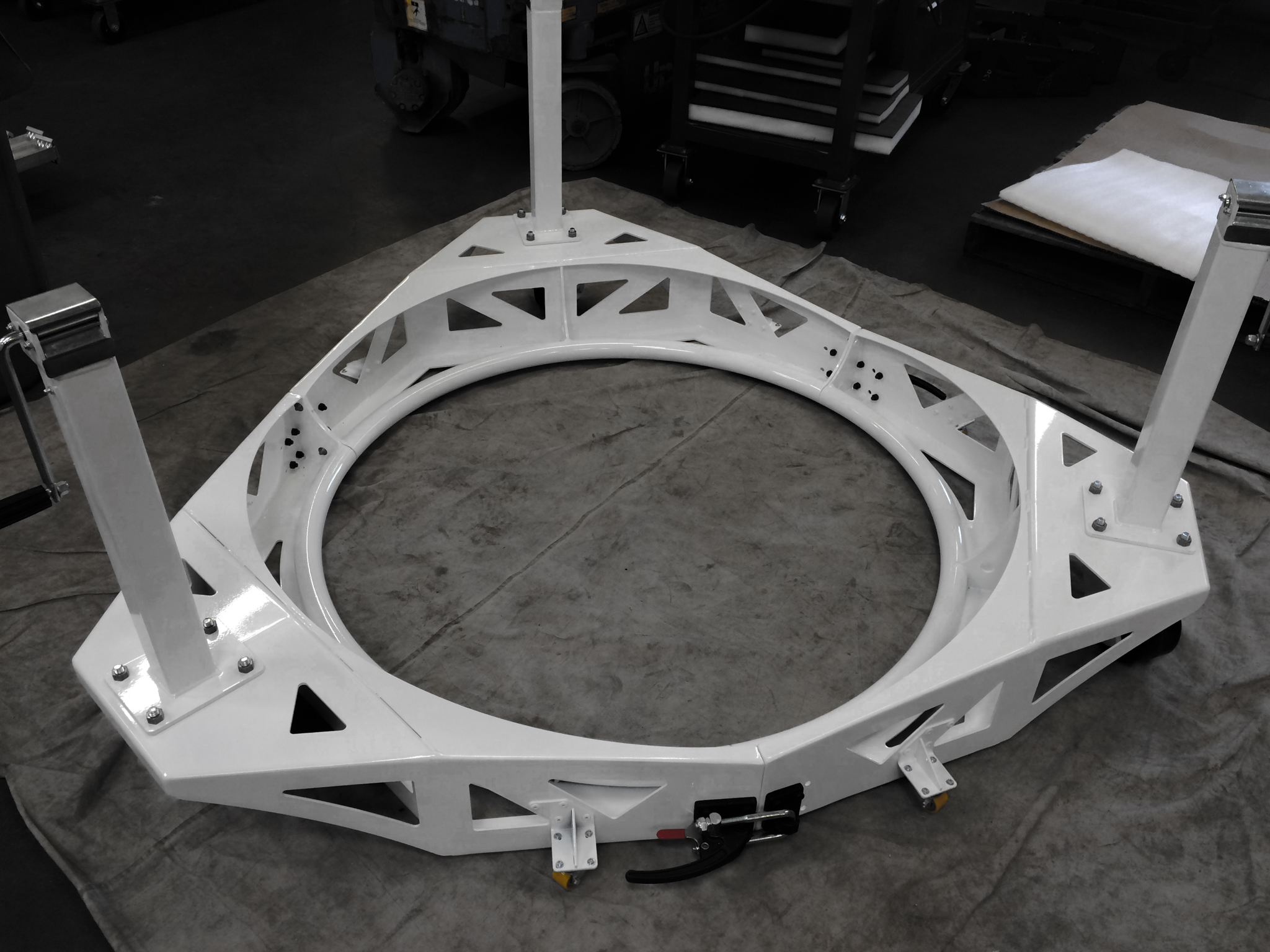

With years of experience designing systems to lift, and manipulate large piece of bridge structures, Daniel Hester was the right engineer to design a solution that would work seamlessly. It took just a few long days to design and engineer a system utilizing Solidworks that could be built in the shop and tested in less than a week from the initial phone call. The final design was of a 3-piece assembly that could be disassembled to be air-freighted, as well as be able to move through a standard doorway. The system allows a single user to move a 2,400 LB object with ease without the need for specialized training of additional equipment. In addition to it’s strength, it also had to be designed to be cushioned at the points where it touched so that it didn’t damage the structure of the part, or it’s surface finish. To accomplish this, a high precision ring was made with a rubber pad attached to hold it firm, but cushioned. Because these units ship via air-freight the unit breaks down into a crate that is easy to move with a pallet jack or forklift and requires only one wrench to assemble after it is delivered.

The Results:

The product worked perfectly for the customer who subsequently ordered many more units that were shipped all over the world. Because of the fixturing system that we designed for this project we were able to copy-exact manufacture this product with only a few days lead time on future orders.

- The success of the project resulted in dozens of units shipped around the globe

- Significantly reduced labor costs for the customer

- Eliminated the need for heavy machinery

- Eliminated the need for high skilled craft personnel

- Reduced safety exposure