The Challenge: The challenge was to design a simple, safe, and efficient H-frame press that was to be used hard every day of its long life. Almost every shop in the world has an H-Frame press. And almost ever single one of them is cumbersome, unsafe, and inefficient so we wanted to design a custom H-Frame hydraulic press that would improve safety, productivity, and ease of use.

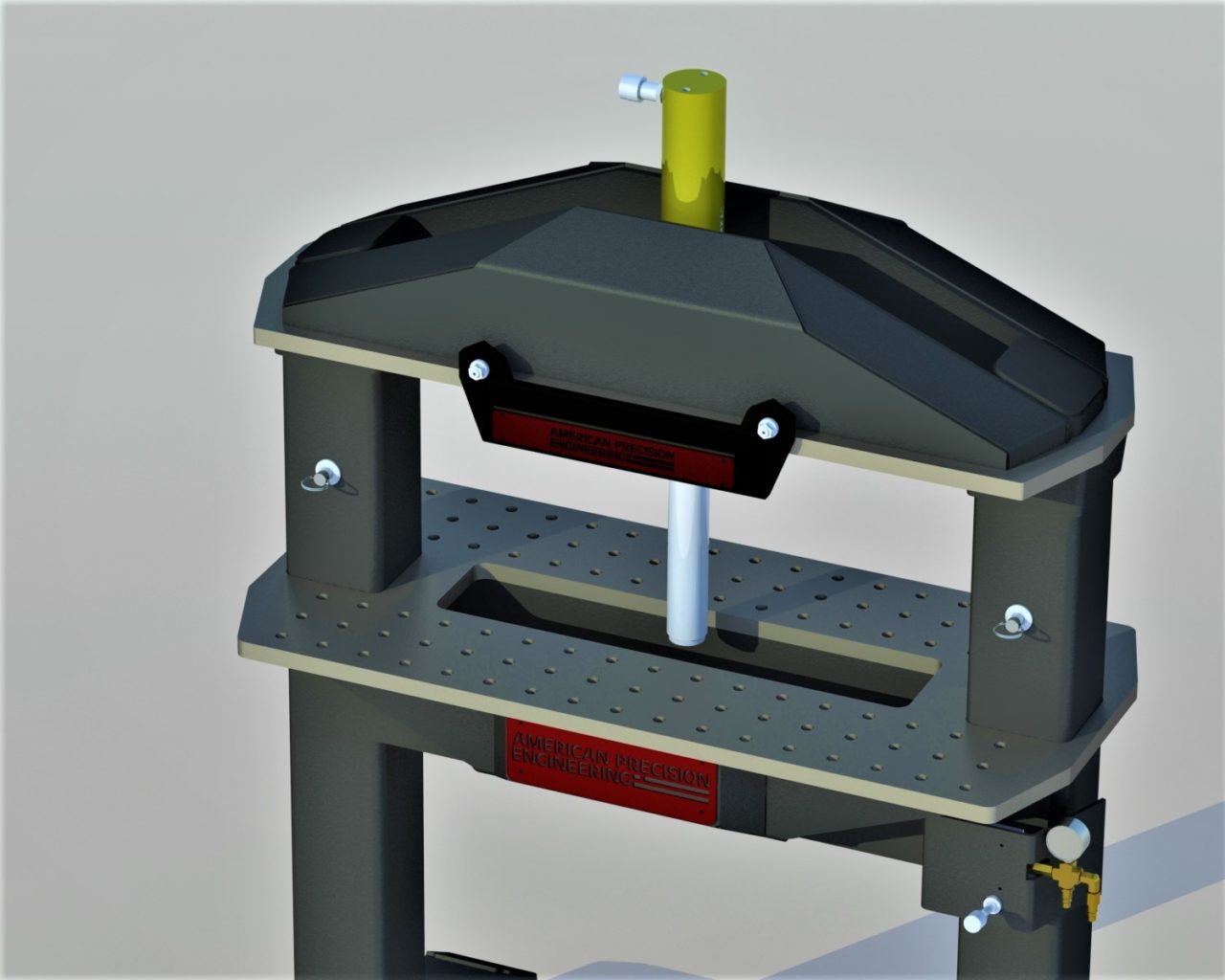

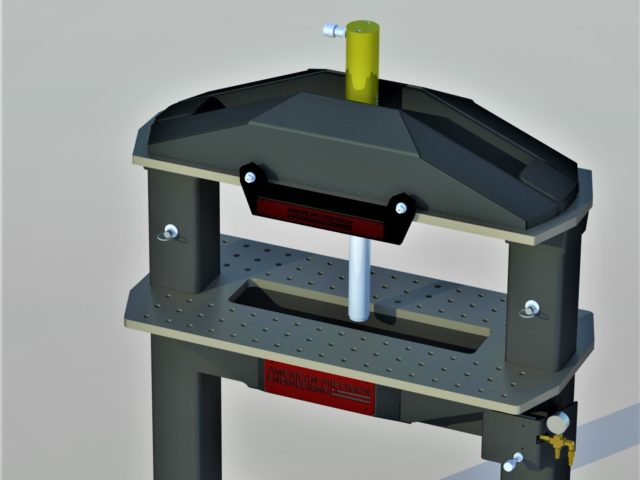

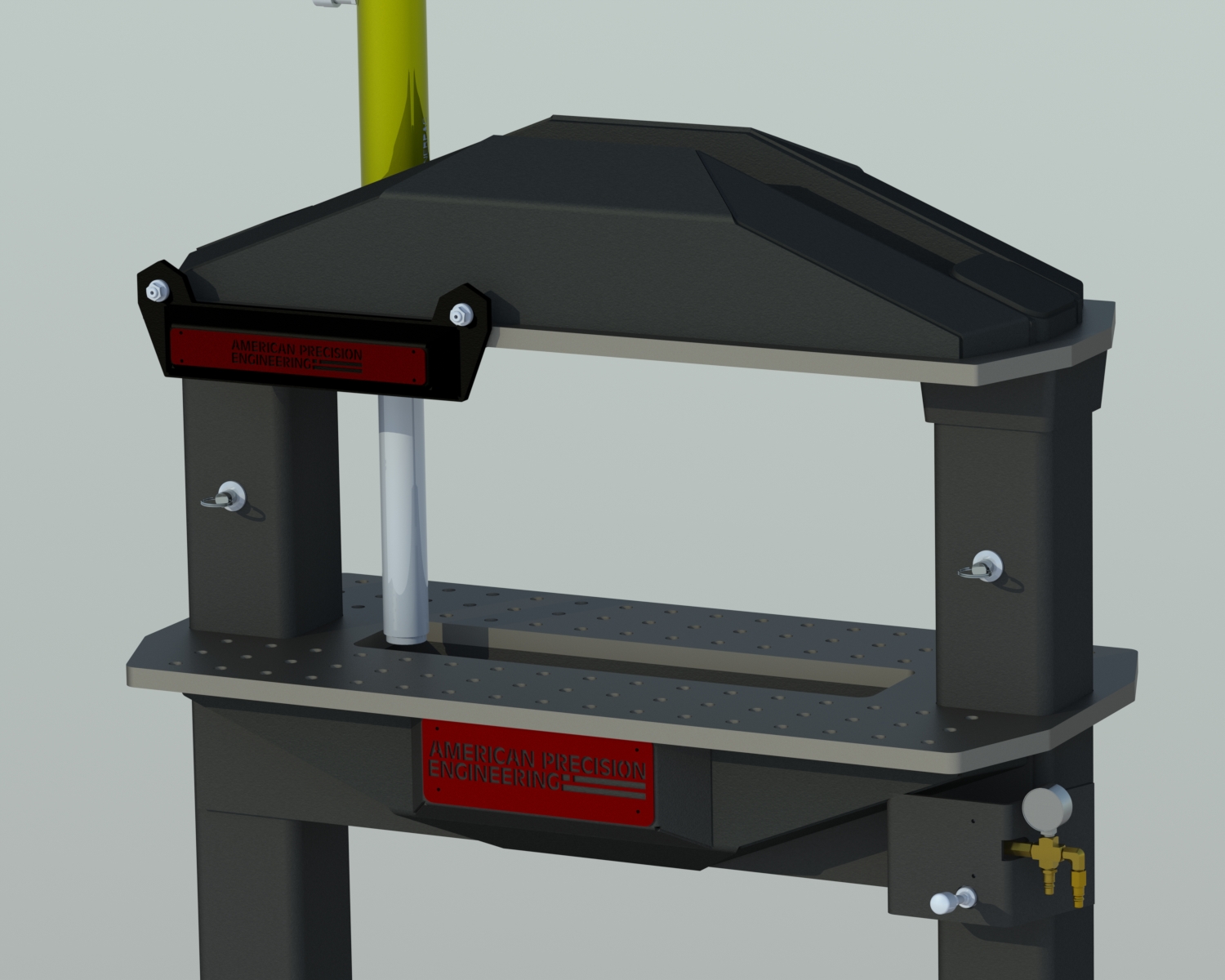

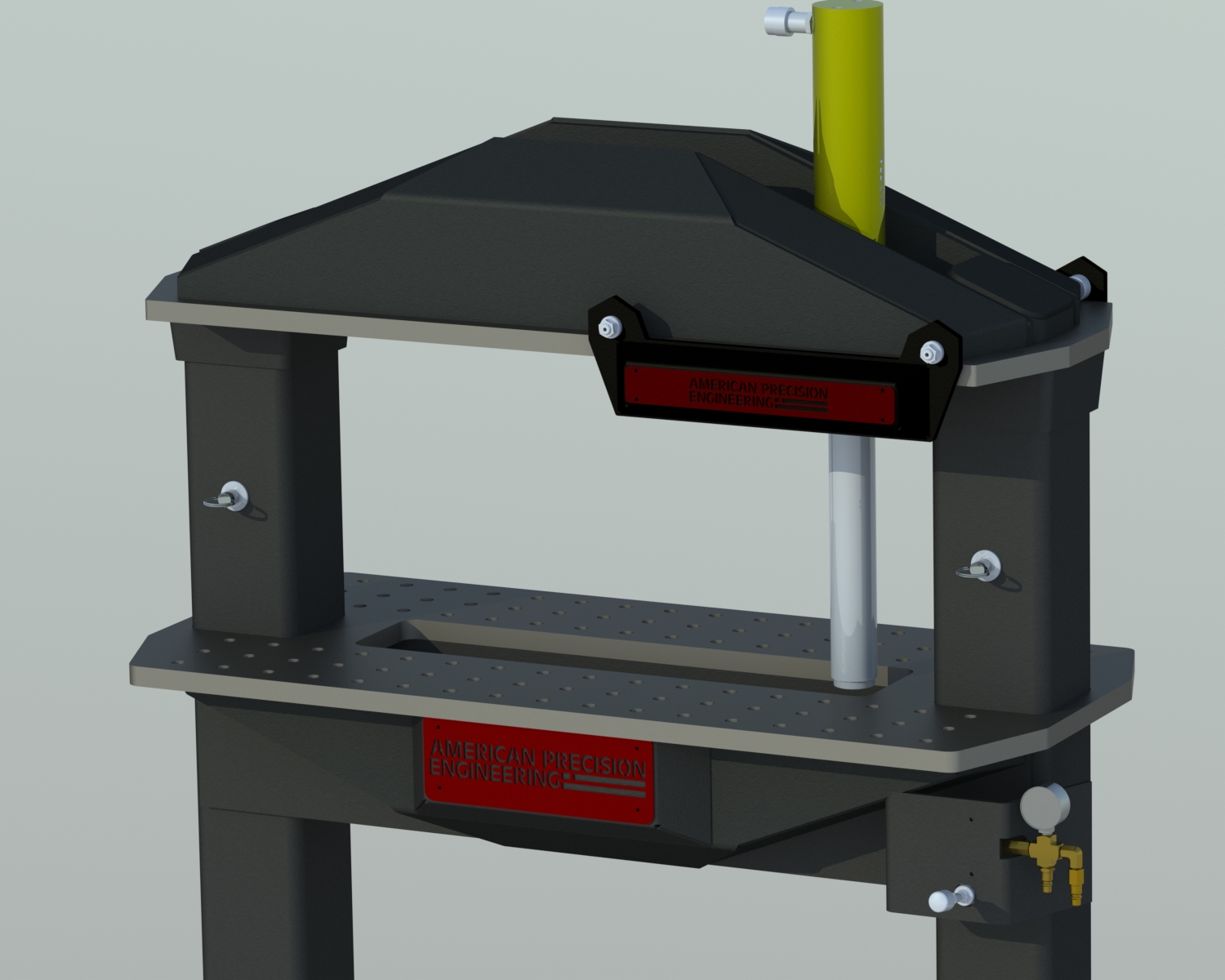

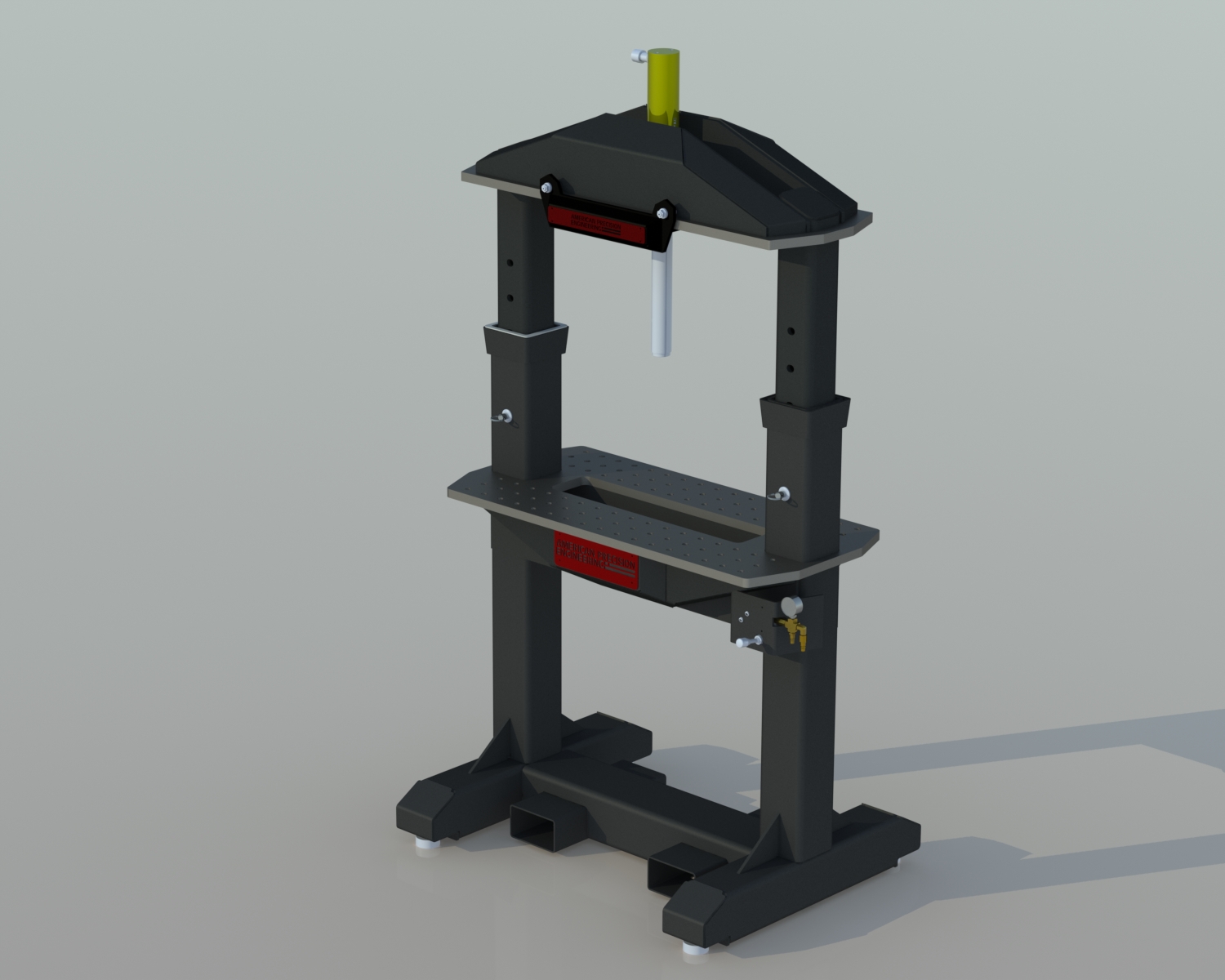

The Solution: The fabrication of the custom H-Frame hydraulic press started by designing the machine using Solidworks CAD software. Because we are always striving to optimize the ergonomics of any manufacturing operation, we decided to design the press the opposite way of every other press. Instead of the work surface having to be adjusted to fit the piece in the press as standard units are designed, we designed our press to have the work surface stationary and have the hydraulic cylinder support be adjustable not just horizontally, but vertically. This allows a wide range of part sizes and shapes to be worked on at an optimized working position, which improves safety, and productivity. While most presses require either multiple people, a forklift, or some combination of these to adjust, we designed our press to be adjustable by a single operator in seconds. To make adjusting simple and easy, we utilized pneumatic cylinders to adjust the massive upper press section through a single hand lever. The horizontal adjustment is accomplished through sliding the hydraulic section on precision cam bearings to its needed location. The 30 ton hydraulic cylinder is powered by an Enerpac air/hydraulic pump that is foot operated. Since the pump is air powered as well, it means that nothing more than shop air is needed to power this entire system. Having a foot-controlled hydraulic cylinder frees up the operators hands to support large pieces when needed which eliminates the need for a helper. Because flexibility is important in lean manufacturing, we designed the press to also be able to be moved quickly, and safely with nothing more than a pallet jack. This allows the press to easily be moved to the best location in the shop depending on the current work-flow of the projects.

The cylinder can be moved from left to right easily by hand

Upper Assembly in the Lowered Position For Small Components

Upper Assembly in the Raised Position For Large Components

The Results: This custom hydraulic H-Frame press design resulted in a wide range of improvements for the shop including:

Hydraulic H-Frame Press Design

2020 October

The Challenge: We were challenged to design and build a portable jib crane to be used in an industry manufacturing facility. A manufacturing company had to lift a component that weighed 150 LBs constantly throughout the course of their manufacturing process. This amount of weight is just a little too heavy to handle by hand, but too small to make sense moving constantly with a bridge crane. This required that a custom hoisting solution be created to safely, efficiently, and productively hoist the component through the different manufacturing steps. In addition, the work bays were constantly changing to adjust to the projects, so the crane needed to be portable to keep the flexibility of the manufacturing floor layout.

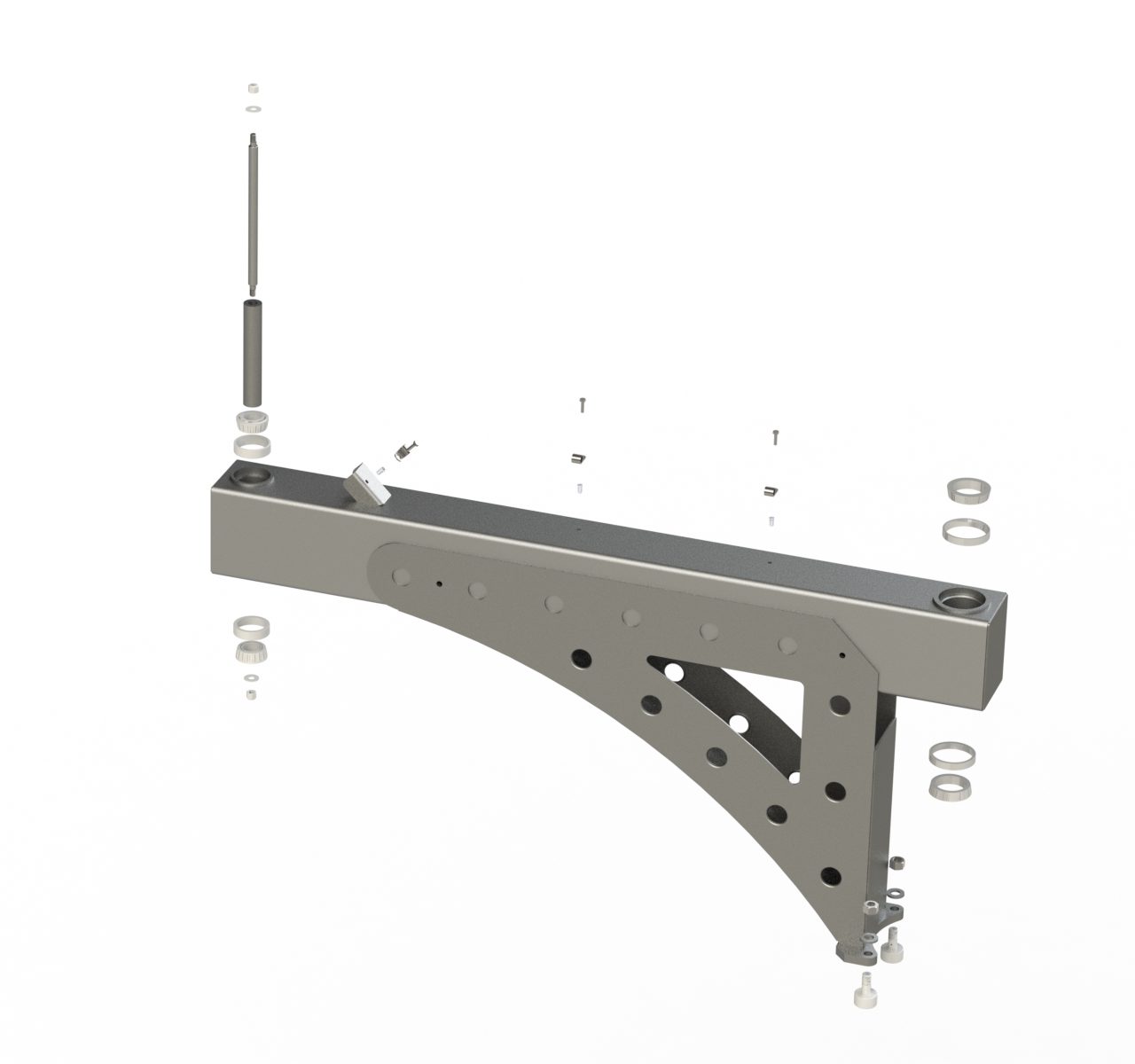

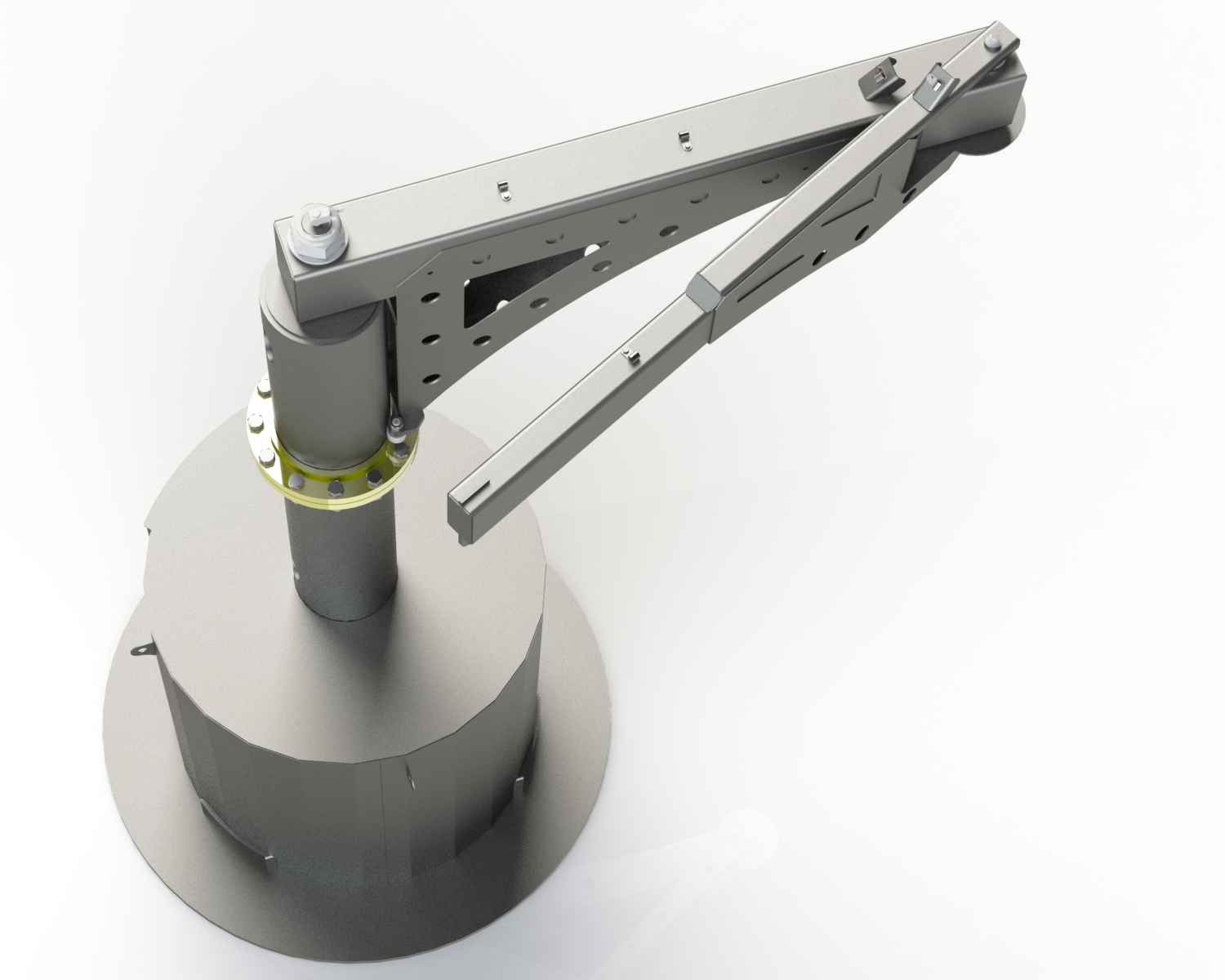

Solidworks allows every piece of hardware to be put into the model to gain efficiency throughout fabrication and assembly

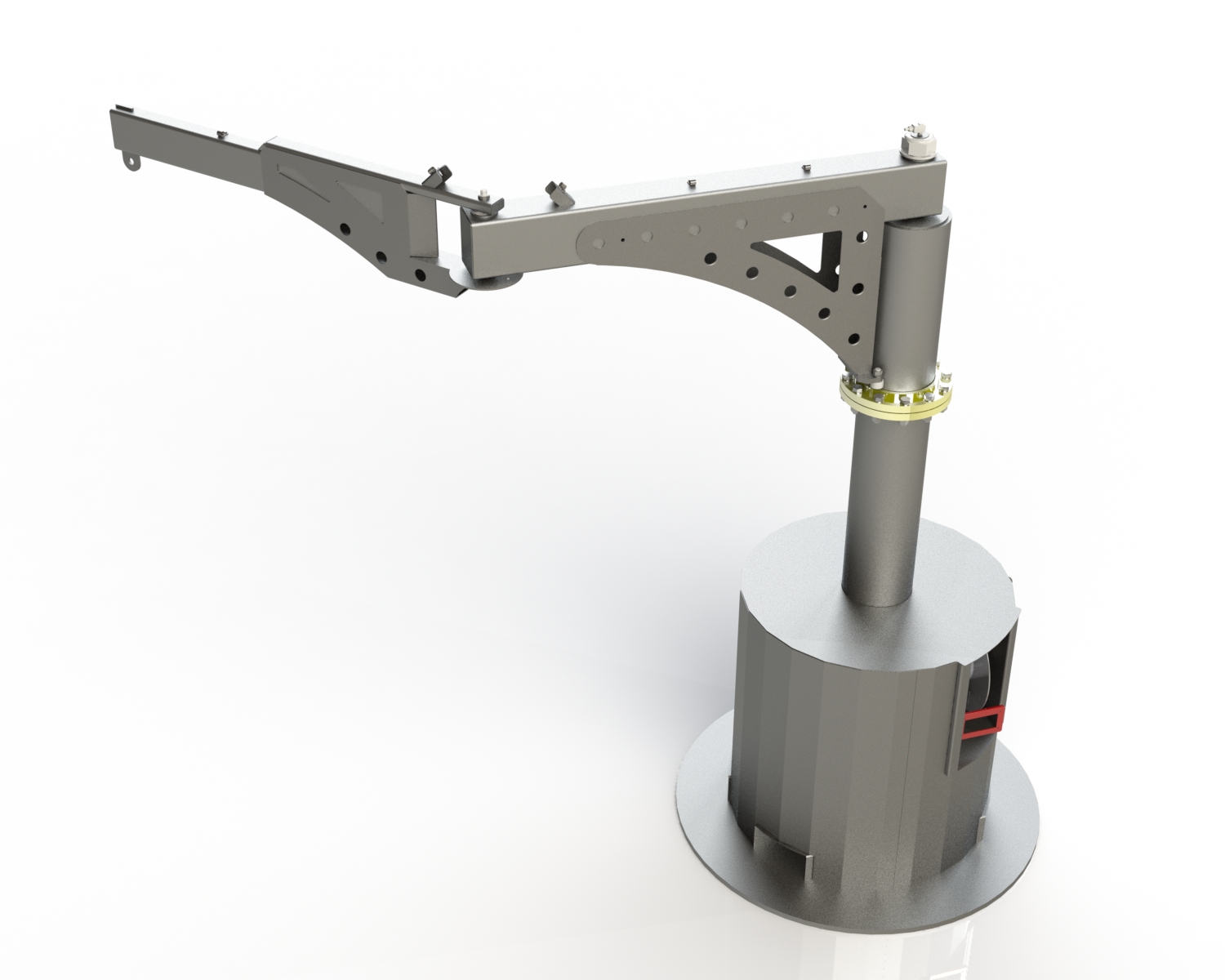

Design: To design the portable jib crane, we had to consider many variables that included power supply, geometric constraints, code compliance, ergonomics, and ease of use. After careful analysis of the different stakeholder concerns, we were ready to start designing the crane utilizing Solidworks for both component design as well as finite element analysis. Once simulated the various load cases, and calculated the capacity per OSHA, ASME, and CMAA standards we sent our design out for 3rd party verification and Professional Engineer’s stamp. Our design allows for 360 degree rotation of the main boom, and 320 degrees of rotation of the secondary boom which allows for a compact, fast, and easy to use crane. Because the hoist, as well as the swing brake are air-operated the only power that is required to run the crane is compressed shop air, and the built-in hose reel makes it fast and easy to position it anywhere in the shop and be running immediately, even outside, or in wet conditions. An additional unique feature that we built into the portable jib crane design was that it has a splice in the main support post. This splice allows it to be disassembled for shipment inside of a standard shipping container. In addition it also makes the manufacturing process easier by allowing the main boom assembly to be built on a bench as opposed to 10’ in the air.

Portable Jib Crane Designed for Lean Manufacturing

The Double Articulating Crane Boom Allows for Working in Tight Areas

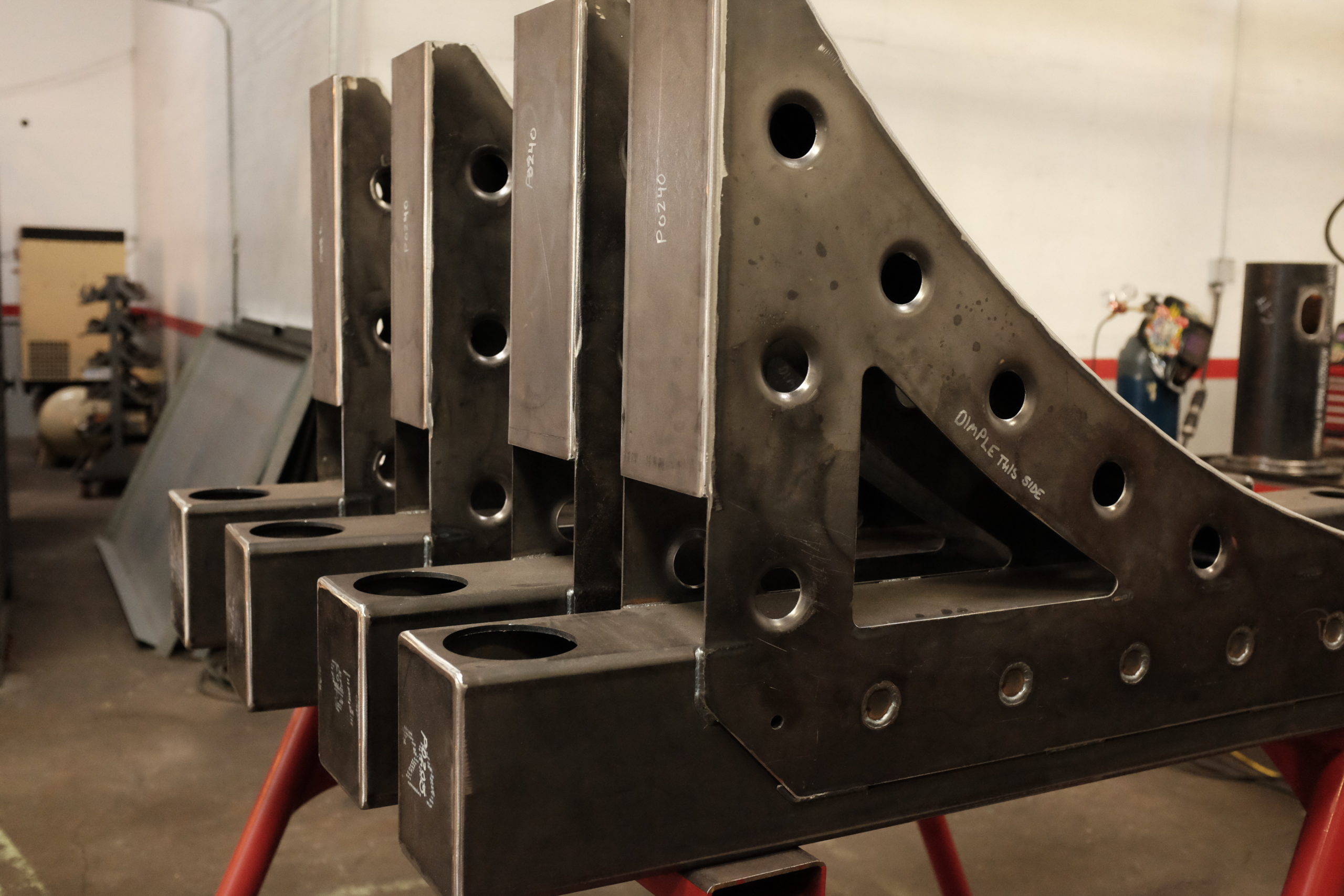

Fabrication: The fabrication of the portable jib crane required a wide range of operations ranging from small part machining, large diameter lathe turning, press brake forming, and lots of critical welding. The sequence of work, as well as the manufacturing tolerances had to carefully be analyzed so that we could assure proper functionality after assembly. Because we always think about how something will be built as we design it, many features were built into the design to aid in the fabrication process to aid in tighter tolerance, and easier part assembly. This includes tab & slot sheetmetal features, Cleco alignment holes, and indexing features to aid in forming sheetmetal components. After the fabrication was complete a series of load tests were completed across the full range of the crane to proof test both structural and tipping capacity.

The Results: In the end, the portable jib crane resulted in a range of improvements in the manufacturing shop that included:

Portable Jib Crane

Five questions to ask your fabricator In today’s economy, you cannot afford to choose an inefficient manufacturer. A company without the design, fabrication, and management skill required to perform the work efficiency, could cost you time and money now (through inefficient production) or in the future (when design shortcomings cause product failures, such as the subject of blog post no. 2). In this post, I share five qualities to look for in a manufacturer to avoid these pitfalls.

Do you need a shop that can weld 4″ plate?

1) Is the company an optimal size for the scale of your project? When it comes to a custom manufacturer of your product, bigger does not mean better. Your project is important to you, and you need a fabrication partner where it is important to them as well. Larger fabrication shops can have tremendous machine capacity that can produce massive amounts of products which can be impressive. However, this can also mean that they are manufacturing parts for very large & powerful companies that can push your project to the very end of a long schedule. Along with the potential schedule impacts you might also not get the level of service that you are expecting. This can be very important with new products since you are almost certainly going to have design iterations that can be very costly to both budget and schedule at larger shops. Make sure you do not select a shop based on square feet of manufacturing space. I recommend that product companies select a fabrication shop that is a smaller company then they are, or at least a similar size. This will help keep the fabricator highly incentivized to perform to their highest level for you.

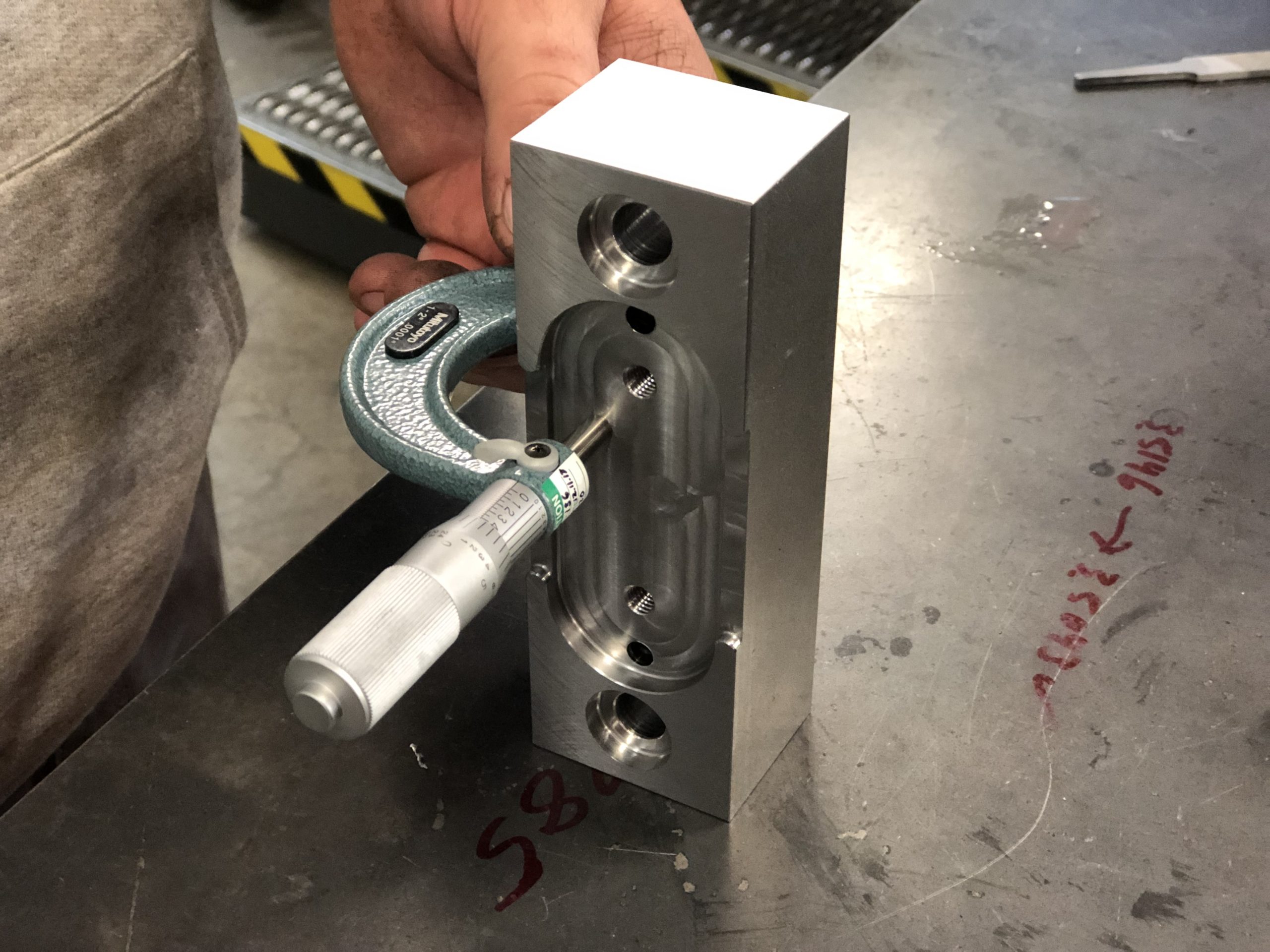

2) Do they have a Quality Management System? You don’t need to be an ISO auditor to ask questions about a fabricator’s quality management system. Whether you are looking to mass produce an existing product, or you are at the early design stage of a new product, your manufacturing partner should have a process for how they assure customer satisfaction. Three key things to ask about are: 1) How do they handle design and drawing revisions? 2) How and when do they inspect parts? And, 3) How do they handle non-conforming work? The best way that these could be answered is with a written, document controlled, 3rd party audited process that can be explained by everyone that works there. Some products do require this level of attention, and some do not. If you are confident that your product does not need this level of quality process documentation then I recommend that you at least tour their facility and ask how they will assure both a quality product and quality service.

Measuring the parts for accuracy to the print is important, but only one part in a successful project

3) Who will manage your project? It is not the machines that make a project successful, but rather the people that manage the project. Every project is measured by quality, schedule, and price, and machines can make a big difference in each of these areas. However, it is the management team that combines them together in a package for you, and it is the combination that will make or break your project. As projects become more complex, the management skill of your manufacturer becomes an even more critical aspect since small problems can easily snowball into giant issues of quality, schedule, and price if not professionally managed. I recommend asking your potential manufacturer what relevant projects that they have managed to a successful outcome. It is also important to know who exactly will be managing the project once you submit your PO. You don’t want to fall prey to a bait and switch move by a sales team trying get your money, so ask specific questions about who will be managing your project. A professional working relationship is critical to success in manufacturing so you should make sure the person that will manage your project will work well for you.

Who will manage your project?

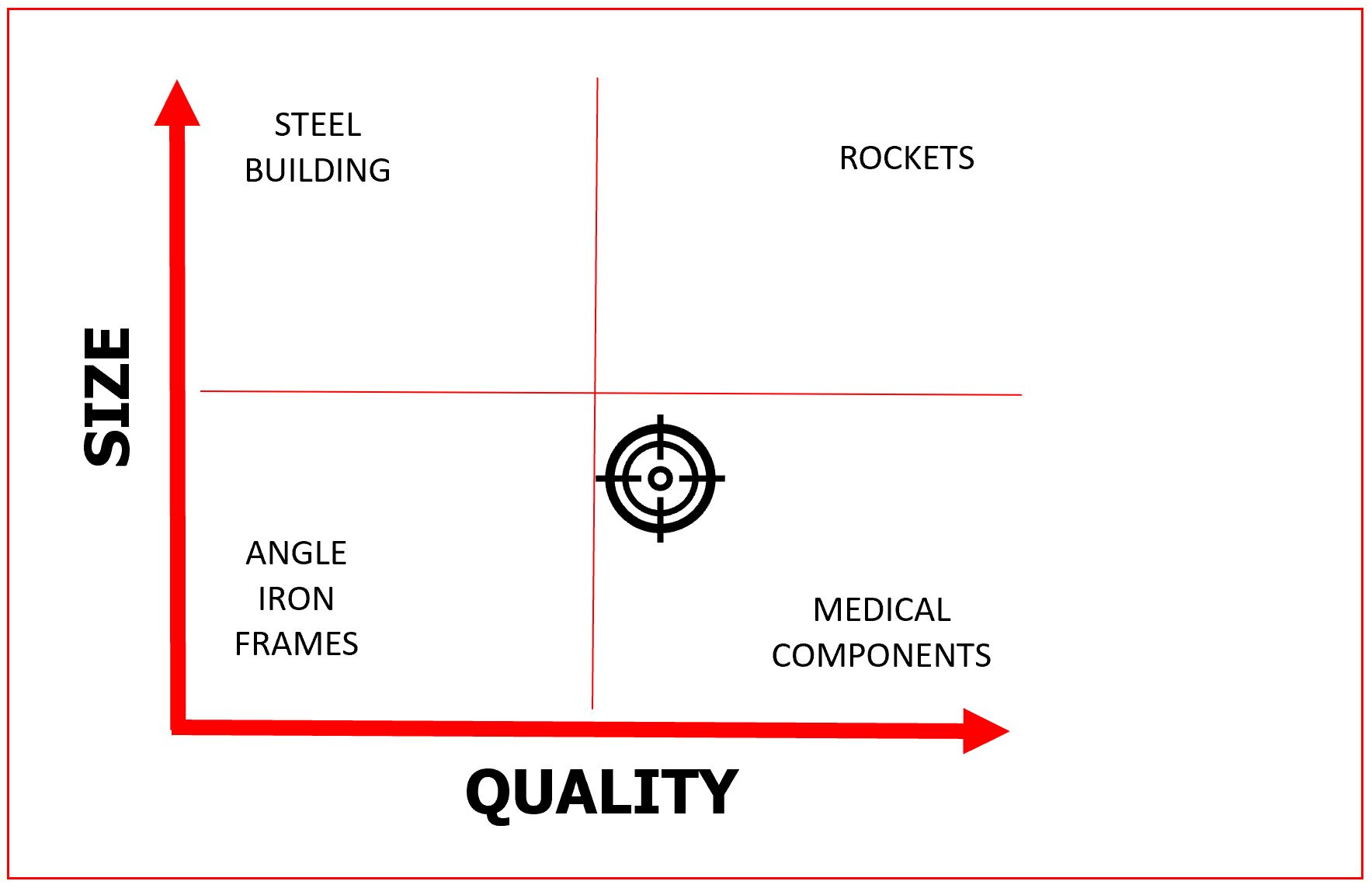

4) What do they specialize in? Taking the first fabricator you find is like going out for dinner in a new city by walking into the first restaurant you come across. If you are indifferent between a fancy steak house and a hot dog with mustard and relish, that might be okay. But if you have specific quality and price metrics that you would like to meet, I recommend asking the fabricator to tell you what they specialize in. If your project is not a good fit for their specialty, they might not be a good fit for you. Like many industries, the manufacturing industry is separated into many different niches. Specifically, they separate into size and quality as shown below, with a 3rd Axis being their typical volume. The business that is good at making one of something is usually not good at making 1,000 and vice versa. And you probably wouldn’t want to get parts for your medical device made at any shop that has angle iron being machined right next to it.

Where is your product on this matrix? Where does your fabricator specialize?

5) How clean is the shop bathroom? Yes, I am being serious. If a business cares about the small details of a business, like how the bathrooms in the shop look, then it almost certainly cares about the small details of the products and services that it provides to you. Having been to 100’s of shops, I can tell you that the correlation of cleanliness to quality is remarkably close. The nicest shop I have ever been too has white tile floors, and the worst had insults scratched into the bathroom stalls about the ownership. While you might not be able to actual visit the john, the same concept can be utilized by just looking around the shop and noticing how clean (or dirty) it is around and behind the machines. If a shop can’t do the little things, how can you expect them to do the big things.

How clean the bathroom is says a lot about how they handle the little details

There is a lot that goes into the decision of where to have your product made. Each product will have a host of concerns that are specific to itself. However, using these 5 tips should get you pointed in the direction of success.

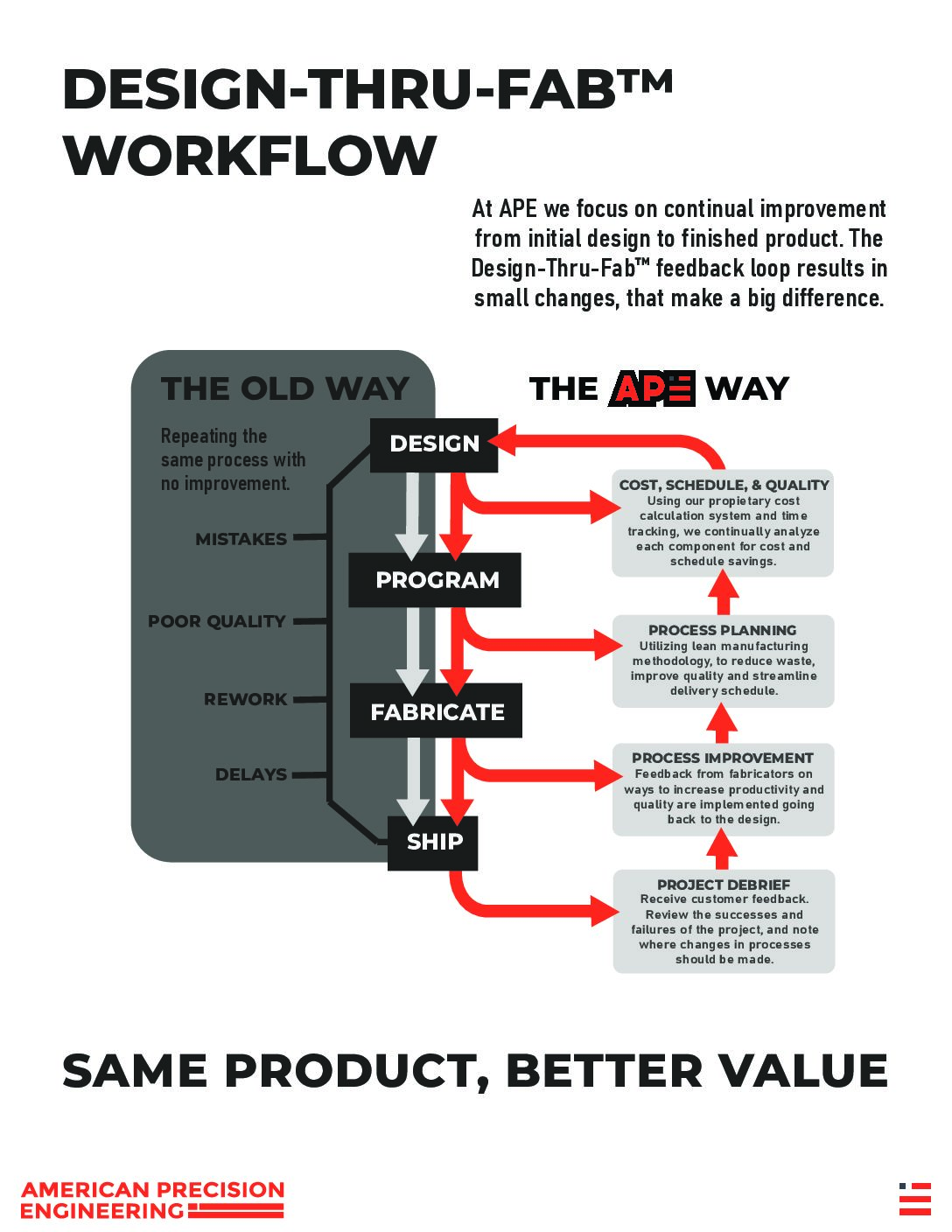

In the early months of the Coronavirus outbreak, we learned of the perils of unanticipated supply chain weakness in the medical field. As governments worldwide worked to stockpile masks, ventilators, gloves, sanitizer, and medication, reliance on a few Chinese manufacturers proved critically problematic. And though in time companies with alternative specialties were able to pivot to provide these goods, many of those efforts yielded too few resources and too late. In a similar vein, many product developers and manufacturers can find themselves with unanticipated weaknesses in their product lifecycle process. They may invest the time of an in-house engineer to detail a model that includes unanticipated weaknesses in the design and/or into their part selection. Or they may rely on a manufacturing process which builds in unnecessary inefficiencies. In either case, developers and manufacturers may integrate unforeseen inefficiencies which cost time and resources, and also leave them open to unnecessary supply chain weaknesses. At APE, we anticipate and alleviate weakness in the product lifecycle for our customers. We provide a range of services to, One mechanism that APE has to improve our customers’ product lifecycle efficiencies is through our Design-Through-Fab (DTF) process.

DTF is work methodology that continuously monitors the project to optimize quality, schedule, and price. Using the DTF method we can utilize APE-specific best practices into the design to enhance production efficiencies. Additionally, APE’s DTF methodology optimizes the interface across project stakeholders, reducing engineering and management resources required by the customer. In this way, DTF creates a continuous improvement loop to make sure changes that improve the project outcome are consistently implemented through each step of the product lifecycle, starting from the design concept and following the project all the way to completion. This assures that the improvements are stable and agnostic to any single part supplier or manufacturer. Therefore, by taking advantage of DTF, our customers avoid inefficiencies associated with the time and resources required to create details that ultimately will not work in the shop context. And using DTF, APE can detail parts to manufacture efficiently, make drawings to flow seamlessly through our shop, and provide the customer with perfectly functioning CAD models and a great product for a good price. Consider a recent project for a large global corporation, that I’ll refer to as Company X. Company X emailed us a SolidWorks model of a stainless steel test chamber used in a manufacturing environment and wants a quote to finish the model and create the required shop drawings. We quoted the job using his model and our proprietary quoting system that is based on historic data and submitted the quote. Because of the design, I anticipated that the customer was going to feel that the price was too high. To head this off, I called the customer to explain why the price is so high. We quote essentially “by piece, and by pound” so that the more pieces the design has, and the more it weighs, the more it costs. So, when a project could be built using 6-8 individual parts, has 48 parts, I know it’s going to be too expensive for what it is trying to accomplish. Despite being disappointed, the seems to understand my reasons for the high price. I assure him that I could submit a price to design the product, and using DTF, I would be able to substantially reduce the production price. But Company X did not see the value of this, as they were convinced that they could improve the design on their own. A few days go by and I get another email from their engineer asking my thoughts on his revised design. I gave him a few pointers, and waited a few more days for the next revision from him. Three weeks and 67 emails later (seriously, 67) he had a design he was ready to fabricate as a first article. The price was still higher than he wanted (and higher than our DTF process would have rendered) but he seemed convinced the prototype would give him the feedback he needed to get the design tweaks down to make it an affordable production run. We are finally off the fabrication phase. But first we are stuck waiting for three weeks for hardware he designed into the door which is only available in Europe. After the hardware arrives, we it will not work with the door design. This requires us to modify multiple parts, make some new parts, and design a custom latch plate. Eventually we finish the project. The engineer is happy with his design and happy with our fabrication, albeit several weeks late due to the delivery of his hardware and the debacle that it caused. About a week after delivery of the first article, company X calls back. During testing, a design failure of the product buckled the door causing a violent explosion. Thankfully, no one was hurt, and no other machines were damaged other than the product itself. At this point, company X became convinced to scrap their design and pay for our services. What was the cost of this lesson to Company X? What unnecessary risks did they take on? What indirect costs were incurred by having their engineer working on this instead of what his normal engineering duties? Just because you can eventually get to a “good enough” result does not mean that it makes business sense for you to do it yourself. Often your overall cost is much less, and your product is much better when you hand it over to APE. Having an engineering department doesn’t make you an expert any more than owning a knife makes you a butcher.

What is Design-Through-Fab (DTF)?

A Case Study on the DTF Value

13610 Immanuel Rd, Pflugerville, TX 78660

ADDRESS