Hydraulic Press Design

Hydraulic H-Frame Press Design

The Challenge:

The challenge was to design a simple, safe, and efficient H-frame press that was to be used hard every day of its long life. Almost every shop in the world has an H-Frame press. And almost ever single one of them is cumbersome, unsafe, and inefficient so we wanted to design a custom H-Frame hydraulic press that would improve safety, productivity, and ease of use.

The Solution:

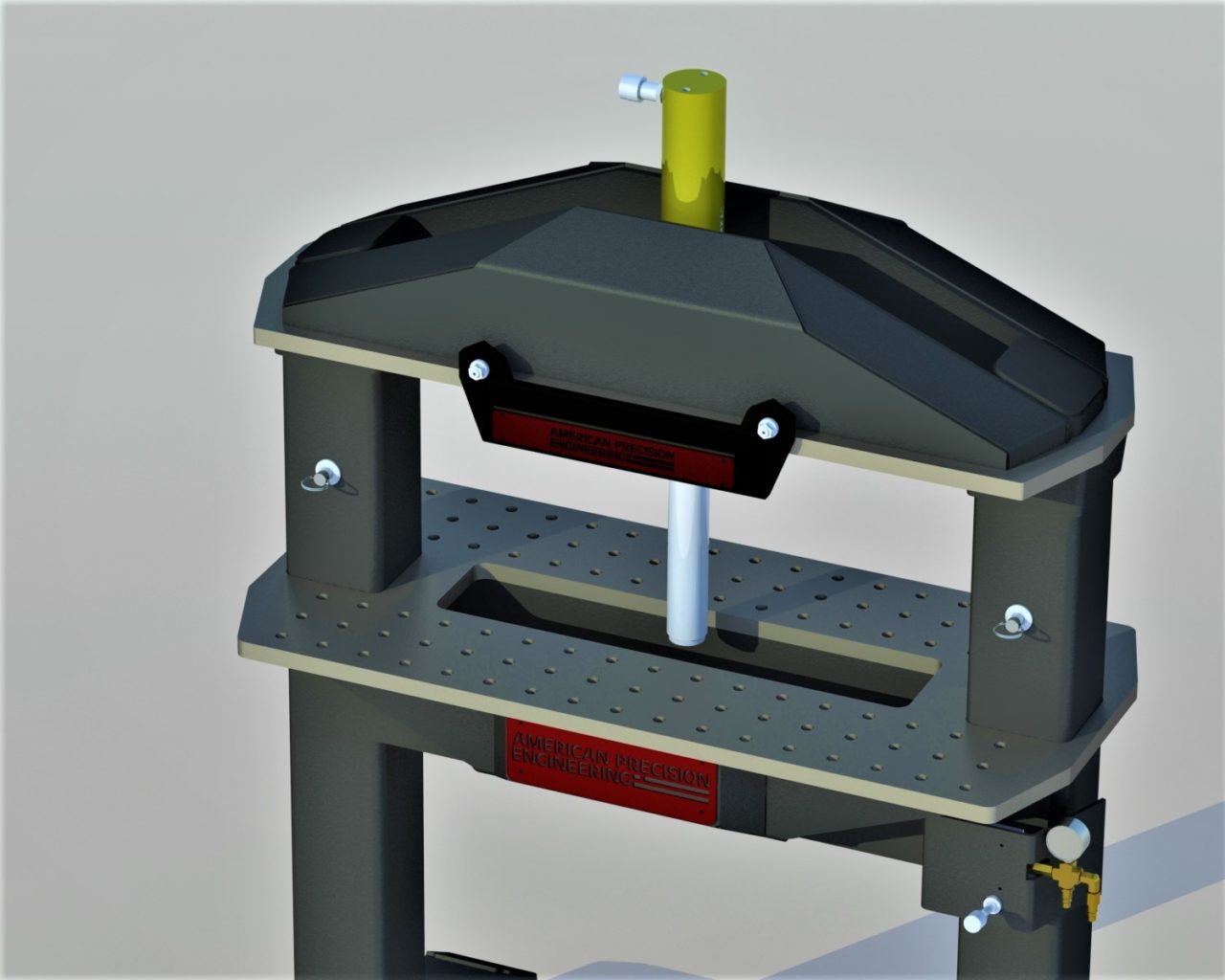

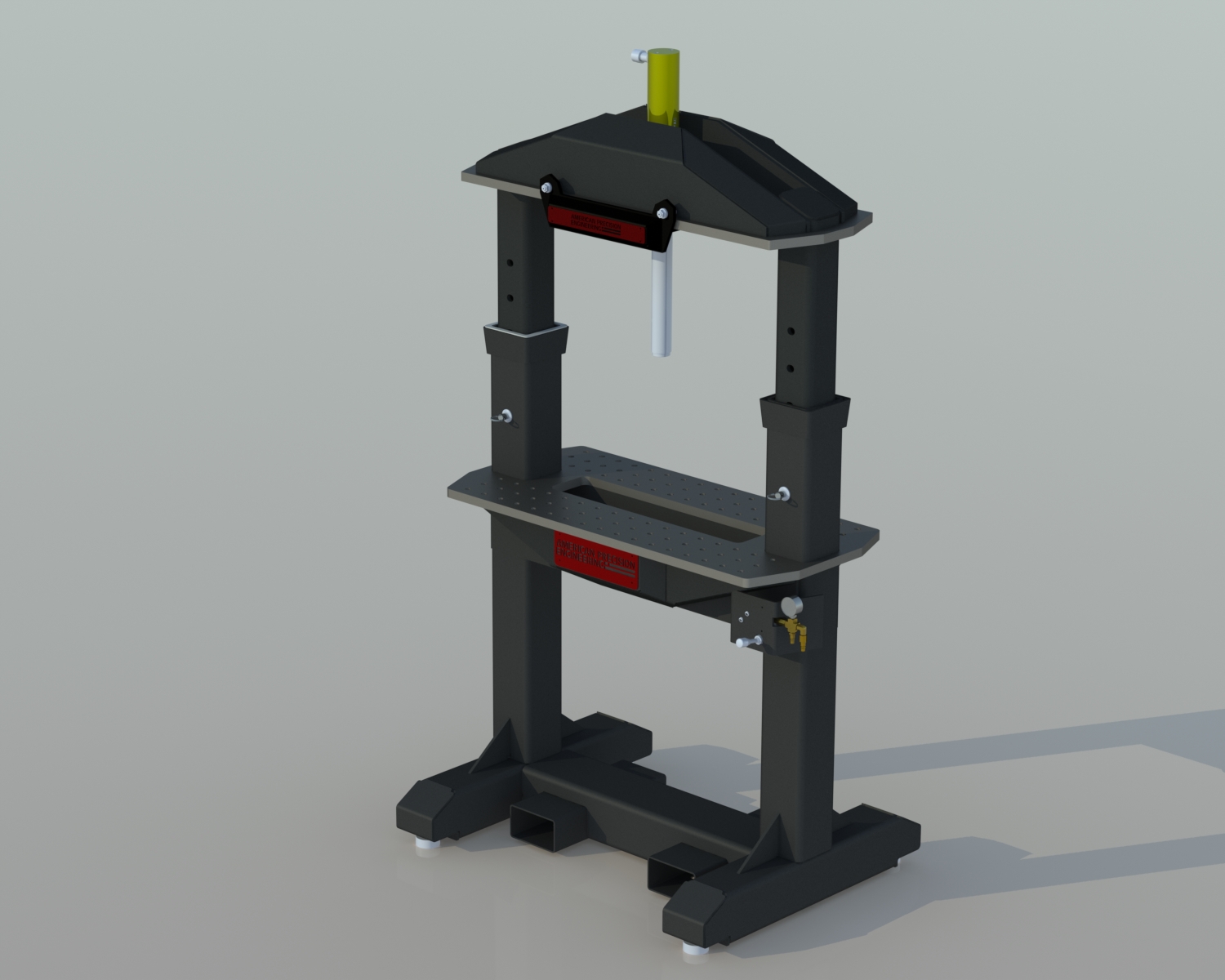

The fabrication of the custom H-Frame hydraulic press started by designing the machine using Solidworks CAD software. Because we are always striving to optimize the ergonomics of any manufacturing operation, we decided to design the press the opposite way of every other press. Instead of the work surface having to be adjusted to fit the piece in the press as standard units are designed, we designed our press to have the work surface stationary and have the hydraulic cylinder support be adjustable not just horizontally, but vertically. This allows a wide range of part sizes and shapes to be worked on at an optimized working position, which improves safety, and productivity.

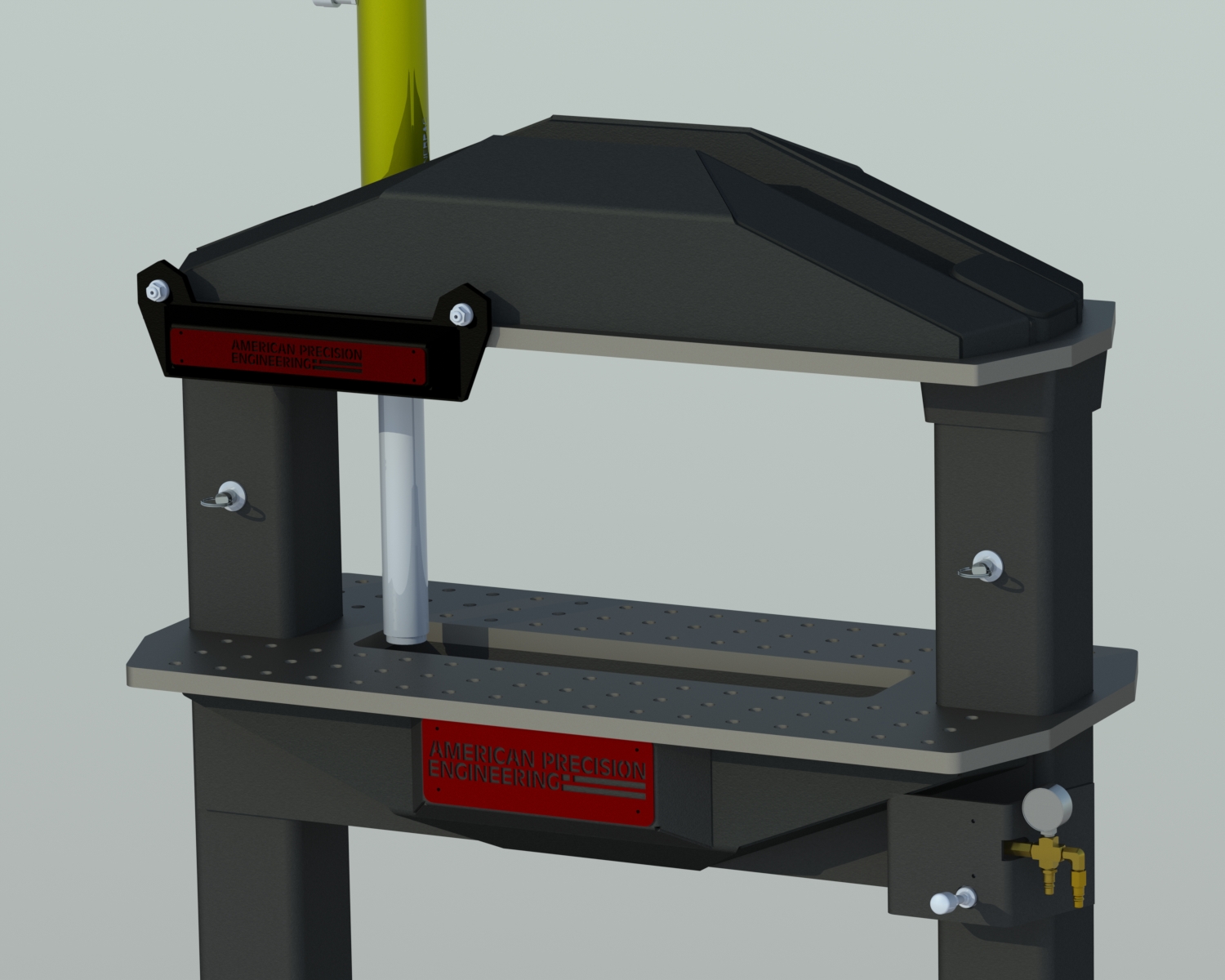

While most presses require either multiple people, a forklift, or some combination of these to adjust, we designed our press to be adjustable by a single operator in seconds. To make adjusting simple and easy, we utilized pneumatic cylinders to adjust the massive upper press section through a single hand lever. The horizontal adjustment is accomplished through sliding the hydraulic section on precision cam bearings to its needed location.

The 30 ton hydraulic cylinder is powered by an Enerpac air/hydraulic pump that is foot operated. Since the pump is air powered as well, it means that nothing more than shop air is needed to power this entire system. Having a foot-controlled hydraulic cylinder frees up the operators hands to support large pieces when needed which eliminates the need for a helper.

Because flexibility is important in lean manufacturing, we designed the press to also be able to be moved quickly, and safely with nothing more than a pallet jack. This allows the press to easily be moved to the best location in the shop depending on the current work-flow of the projects.

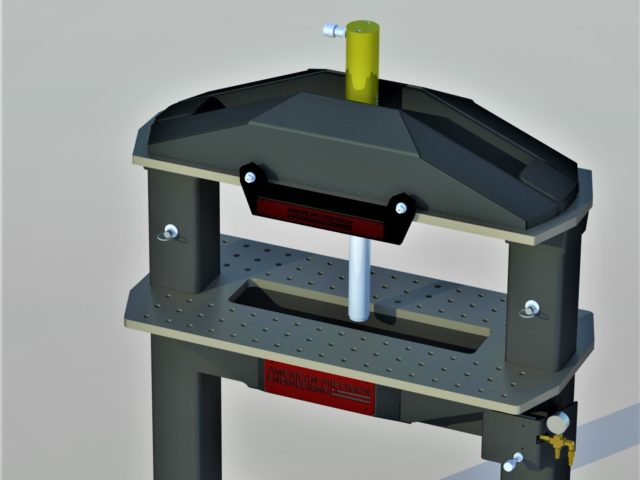

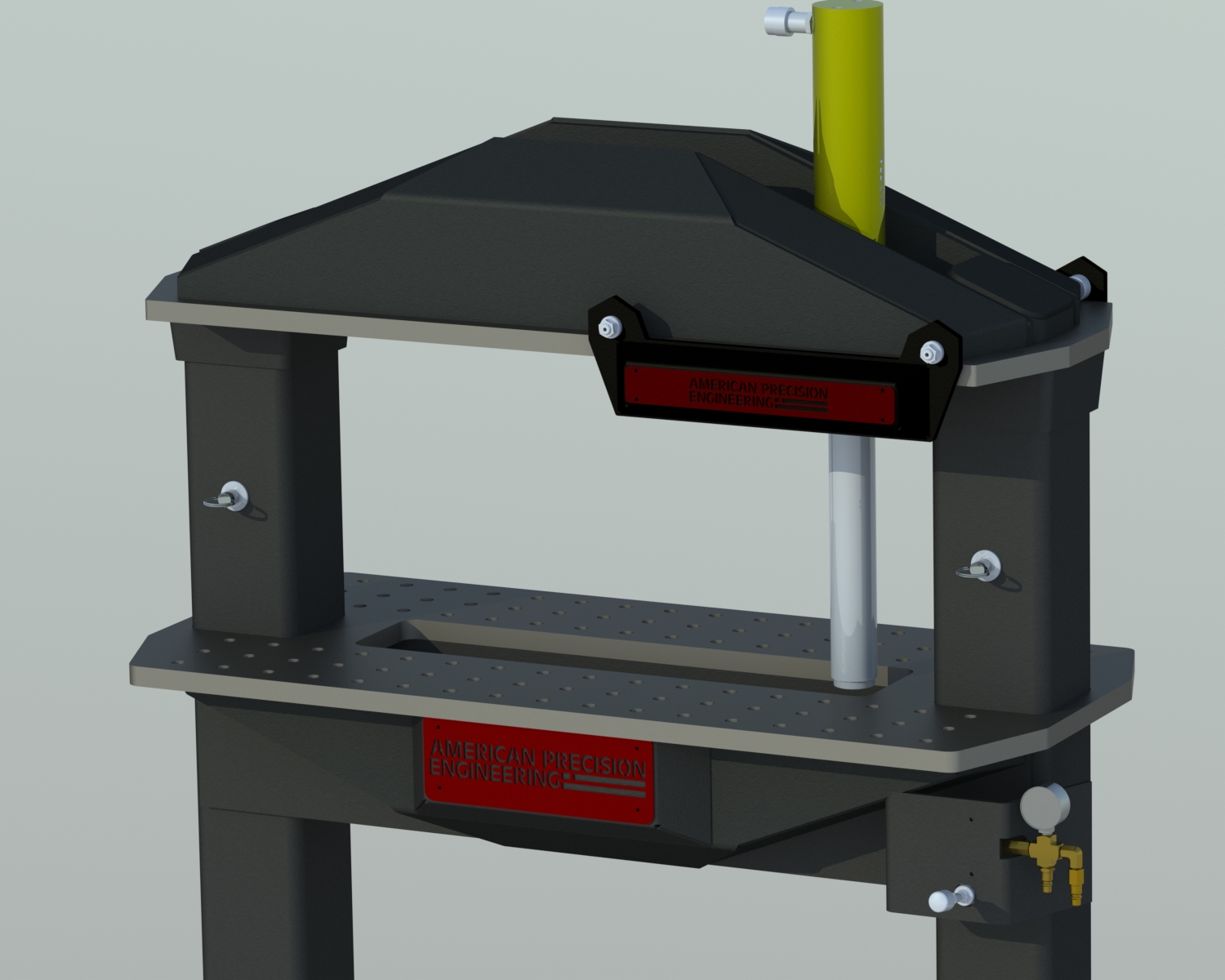

The cylinder can be moved from left to right easily by hand

Upper Assembly in the Lowered Position For Small Components

Upper Assembly in the Raised Position For Large Components

The Results:

This custom hydraulic H-Frame press design resulted in a wide range of improvements for the shop including:

- An efficient, production grade hydraulic press used daily with minimal maintenance.

- Improved operator safety over standard H-frame presses.

- Improved worker ergonomics because of its standard working height.

- Improved productivity in tasks such as broaching, pressing bearings, straightening, and dimpling.

- One of the coolest looking tools in any shop.